ST Cardan Shaft

Welded Rigid Shaft - Type B Series

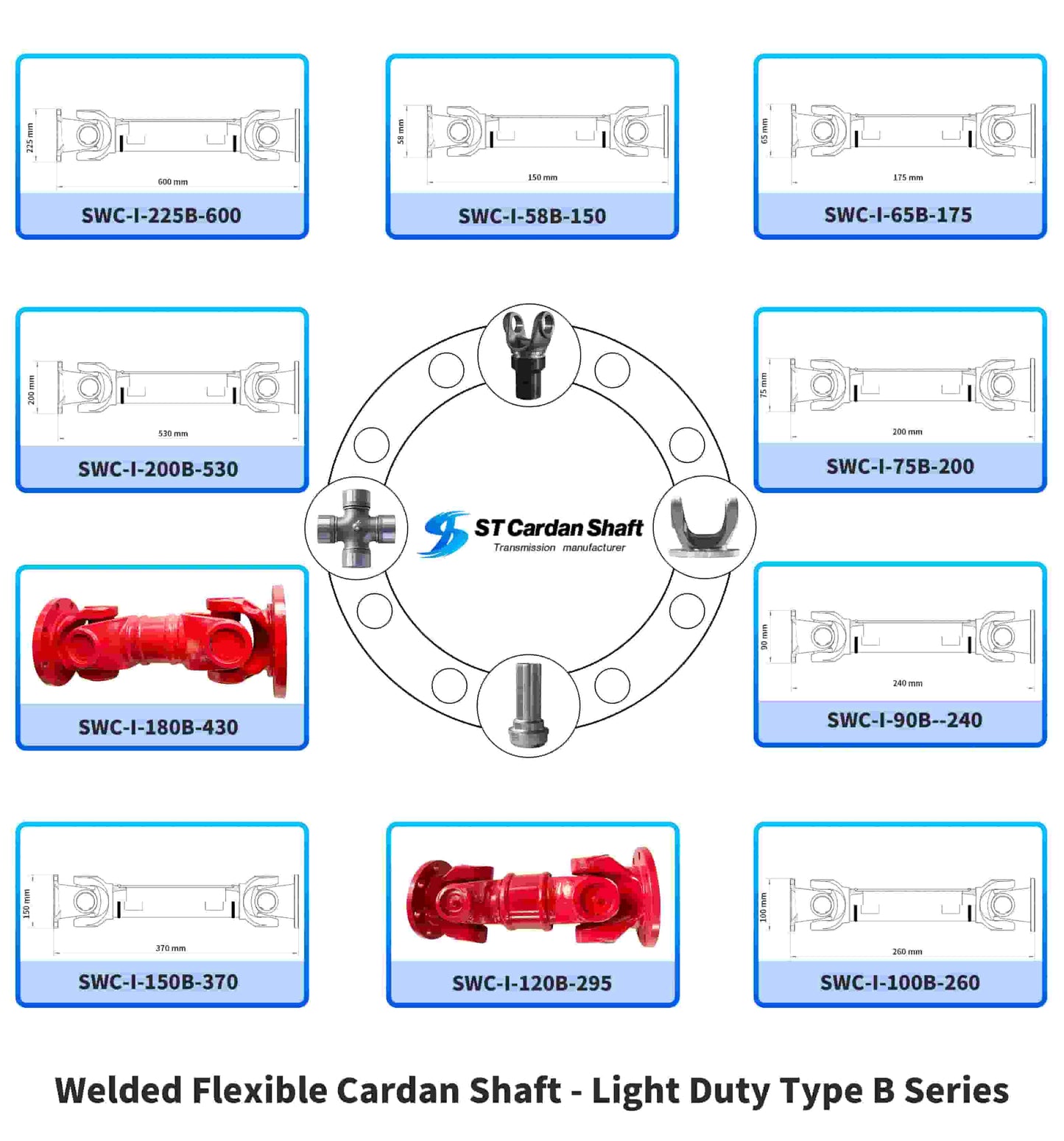

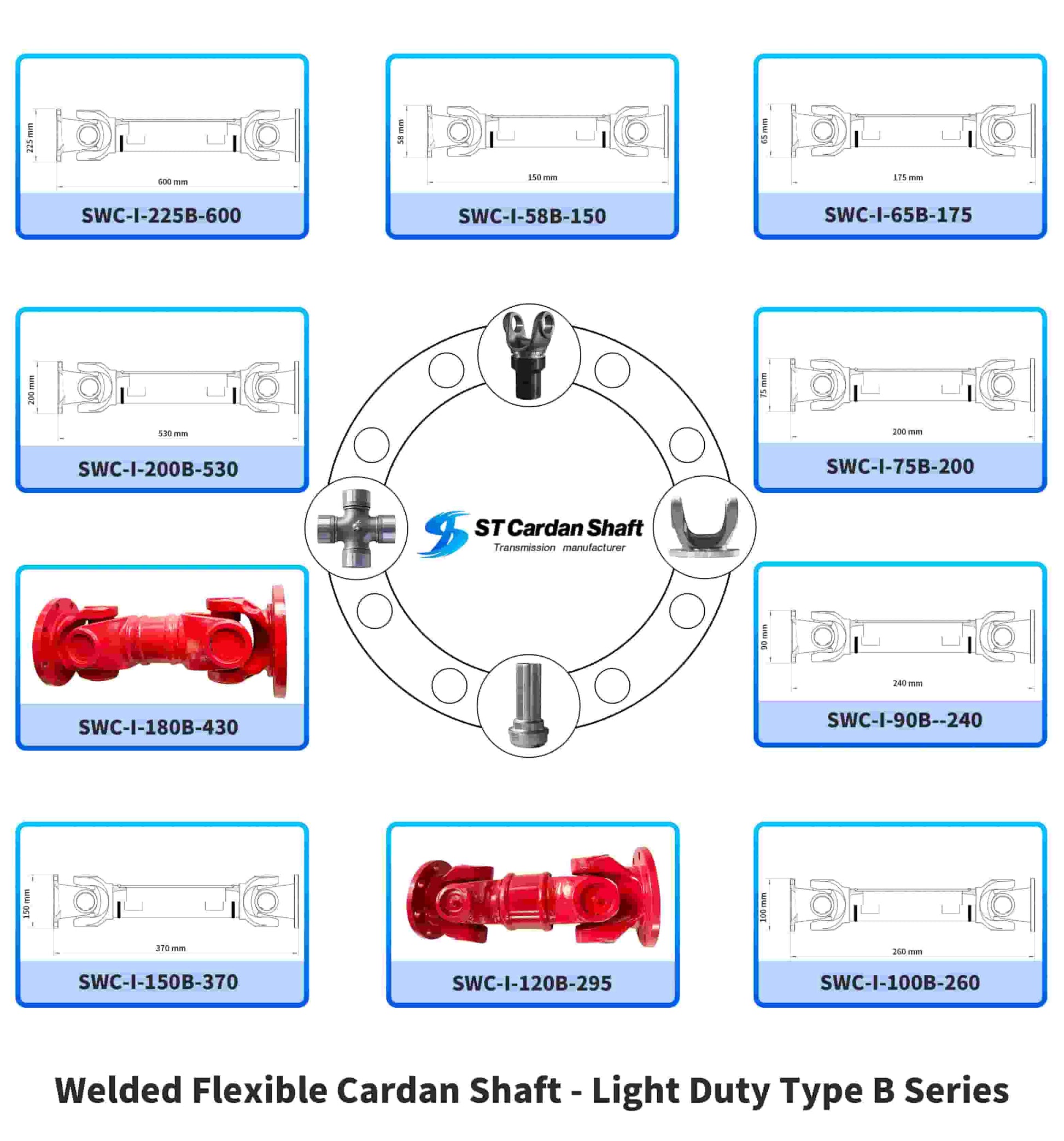

The Light Duty Type B Series is built with a welded rigid design, offering stable power transmission without length compensation. It is well-suited for light industrial transmission lines, conveyor systems, and food processing machinery where consistent shaft alignment is required.

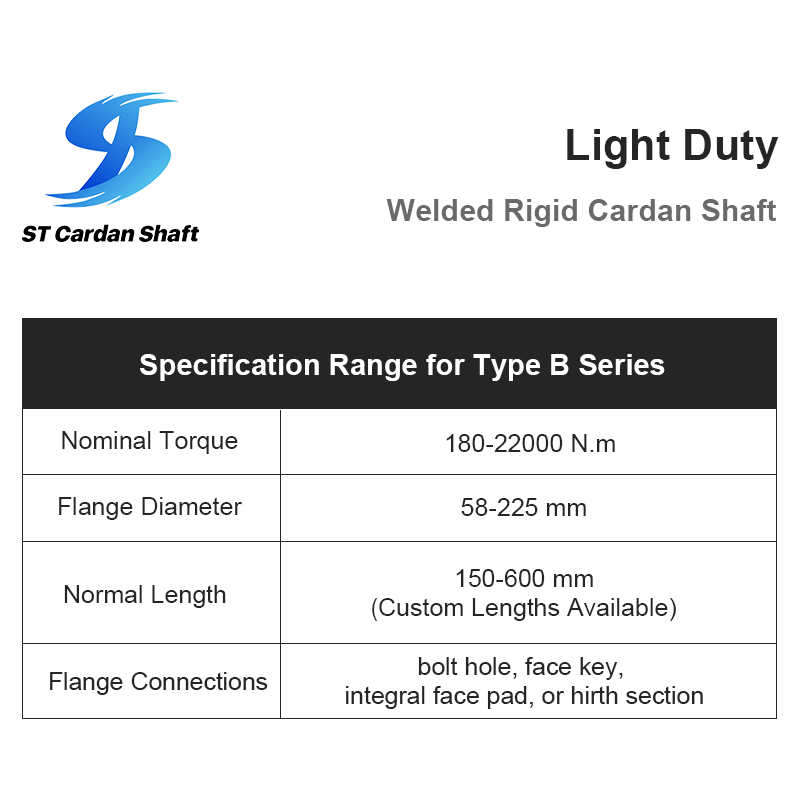

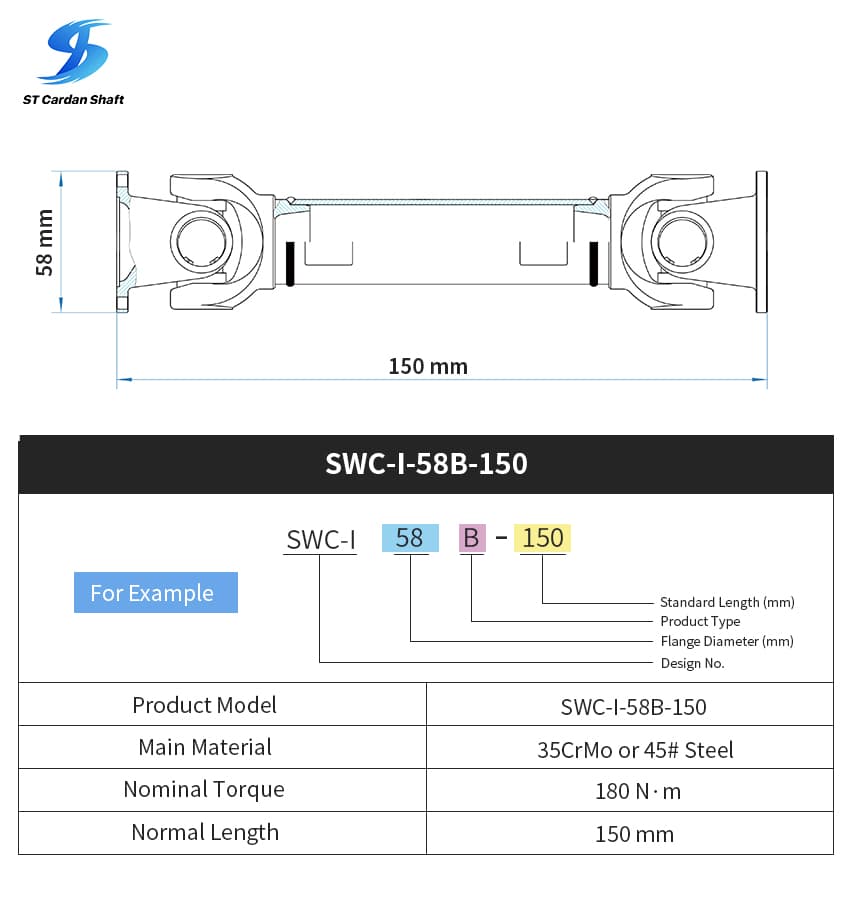

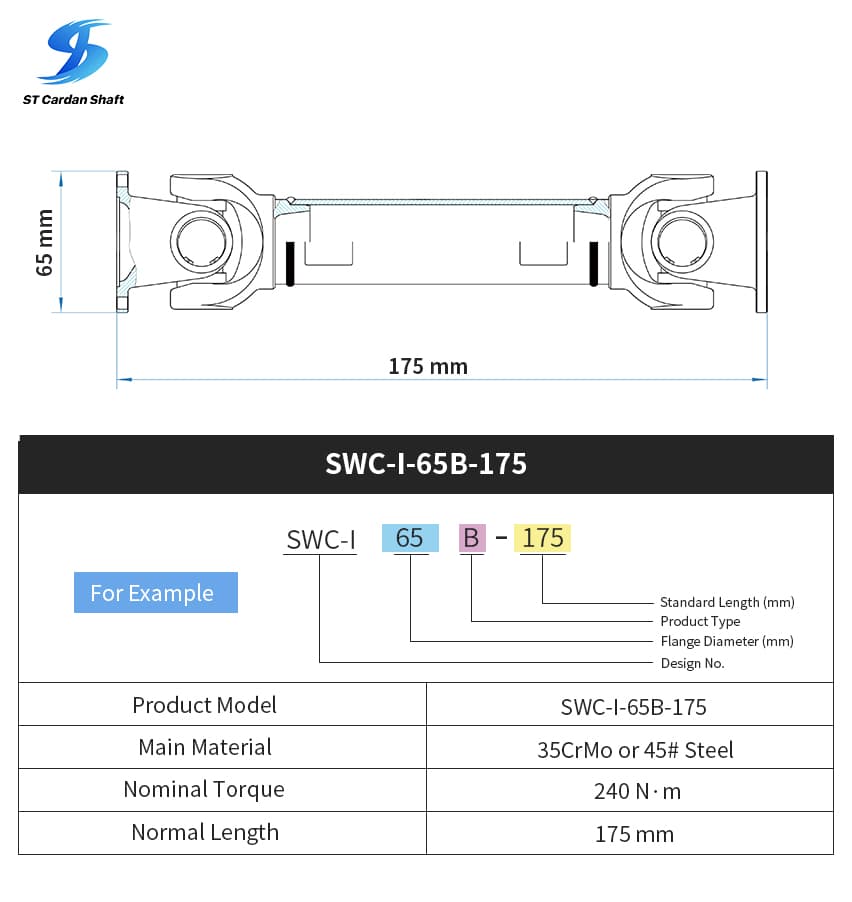

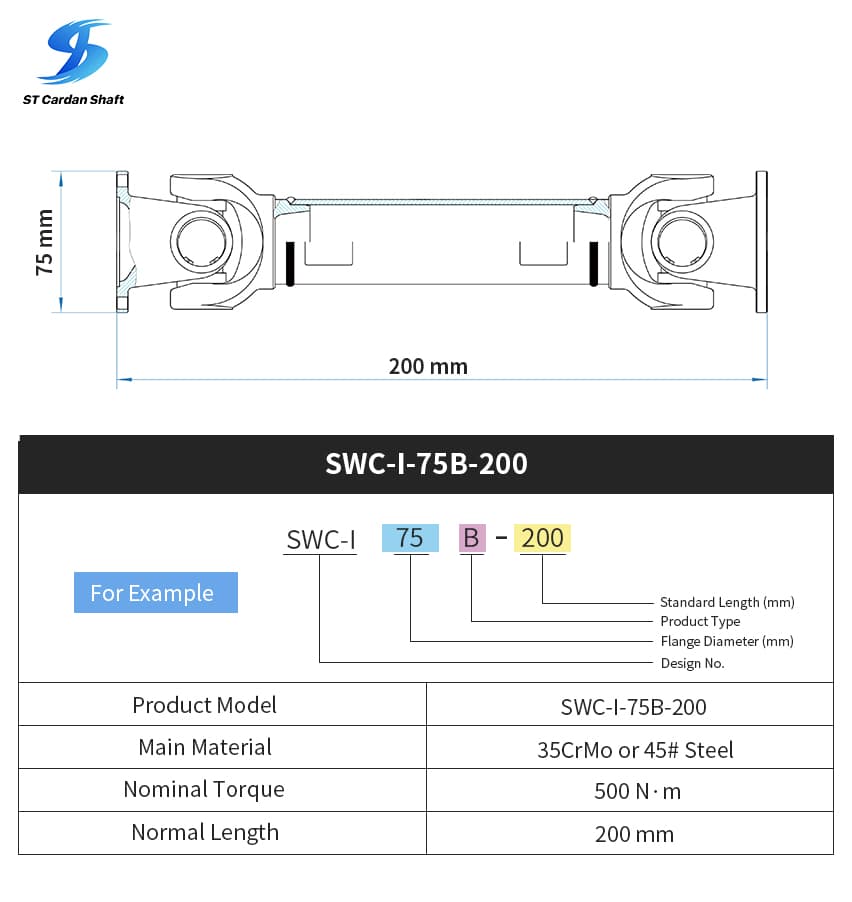

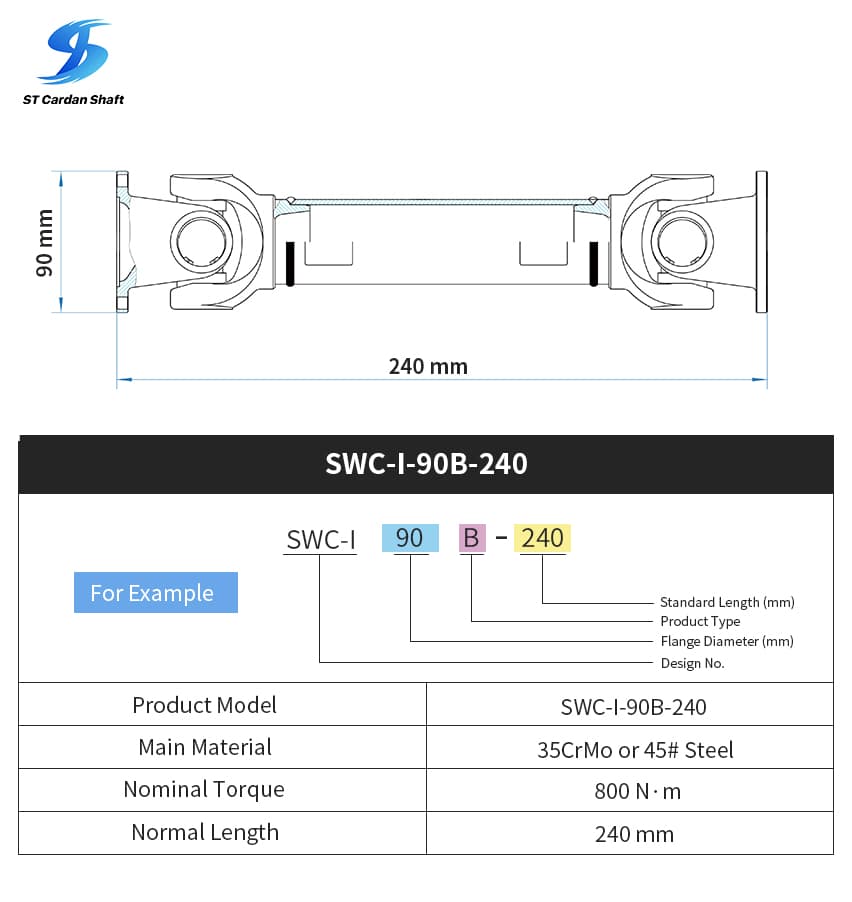

This series includes 10 models with the following specifications:

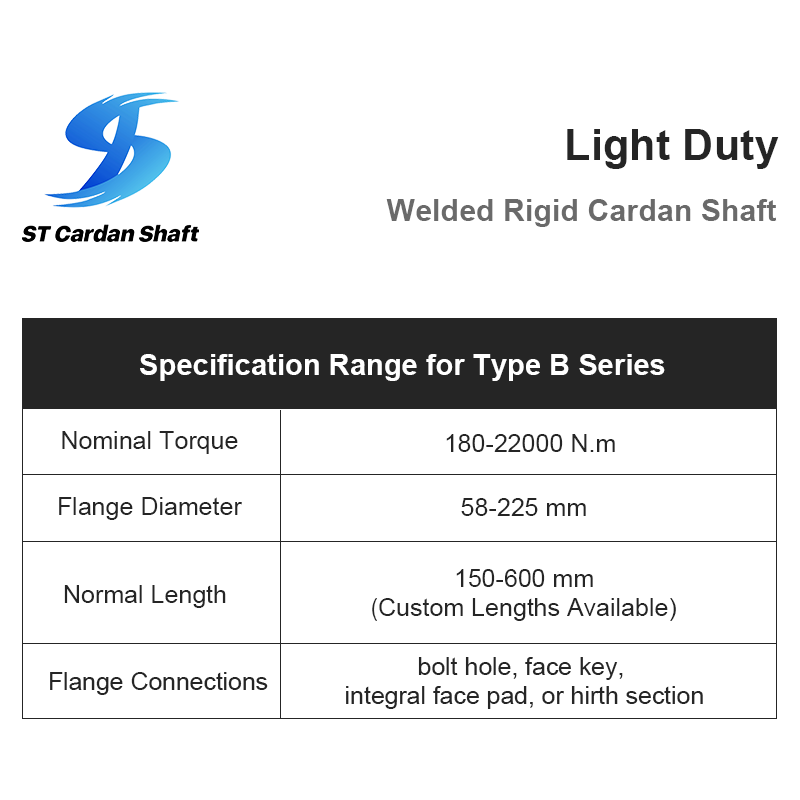

● Nominal torque: 150–22000 N·m

● Flanged diameter: 58–225 mm

● Standard length: 150–600 mm (custom lengths available)

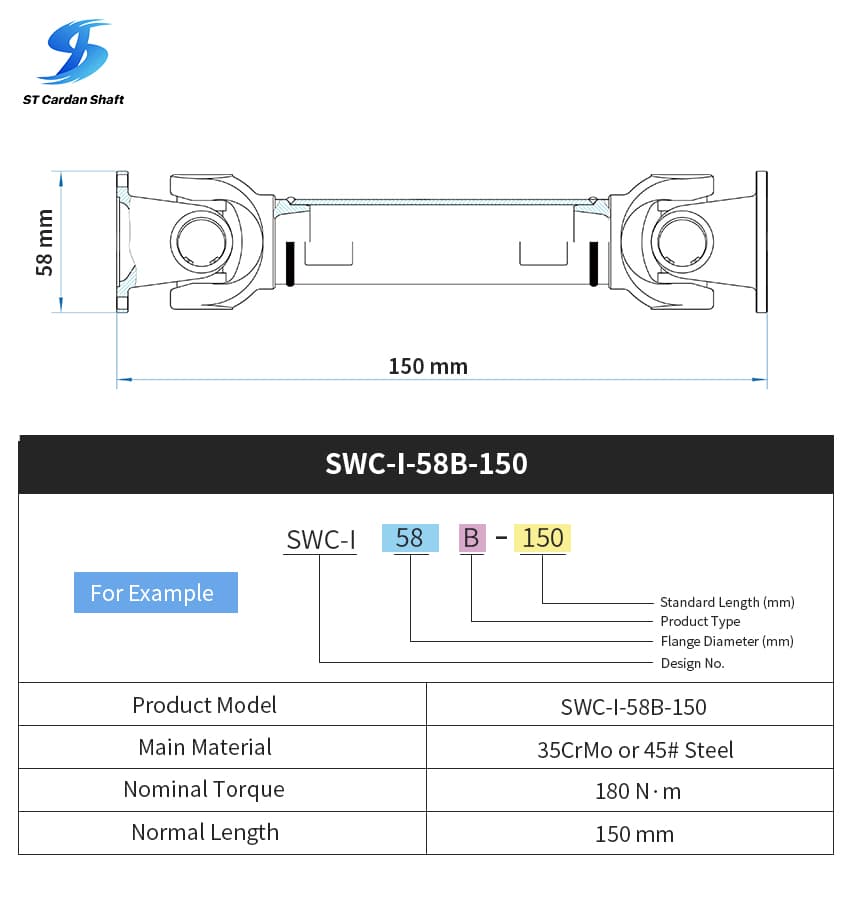

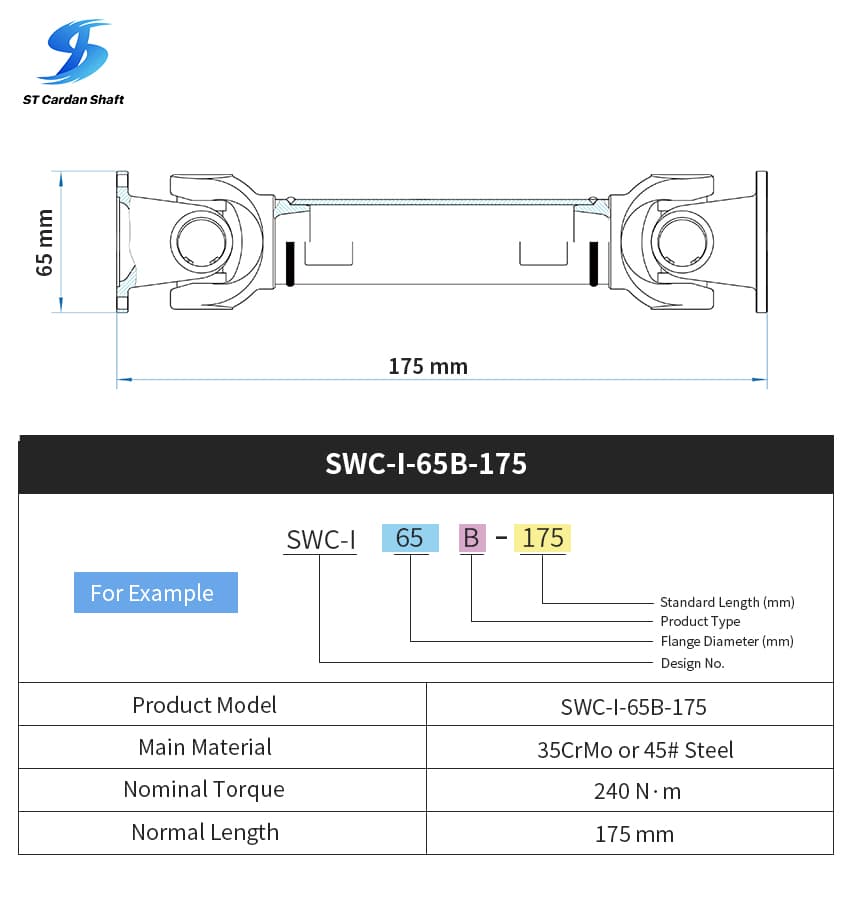

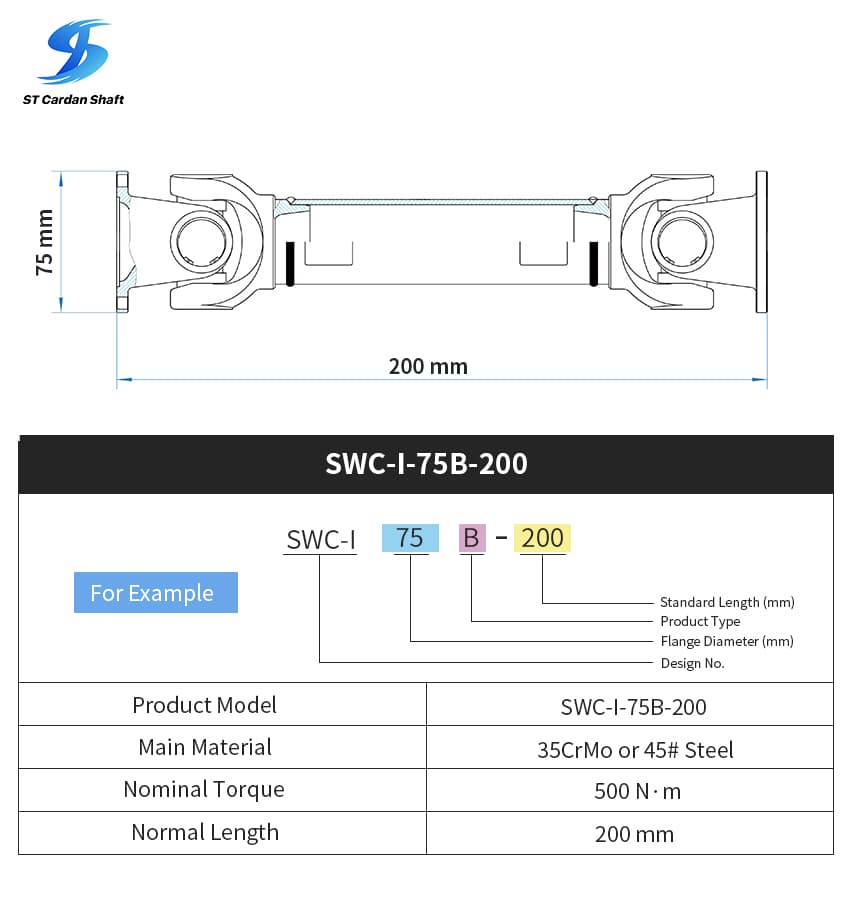

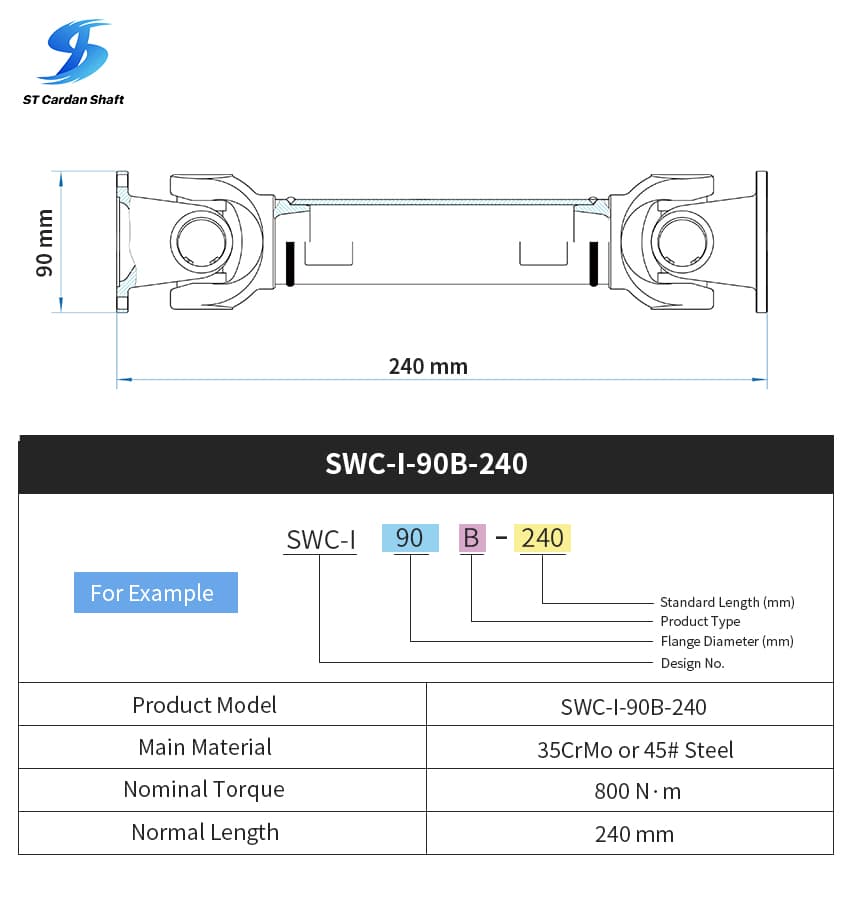

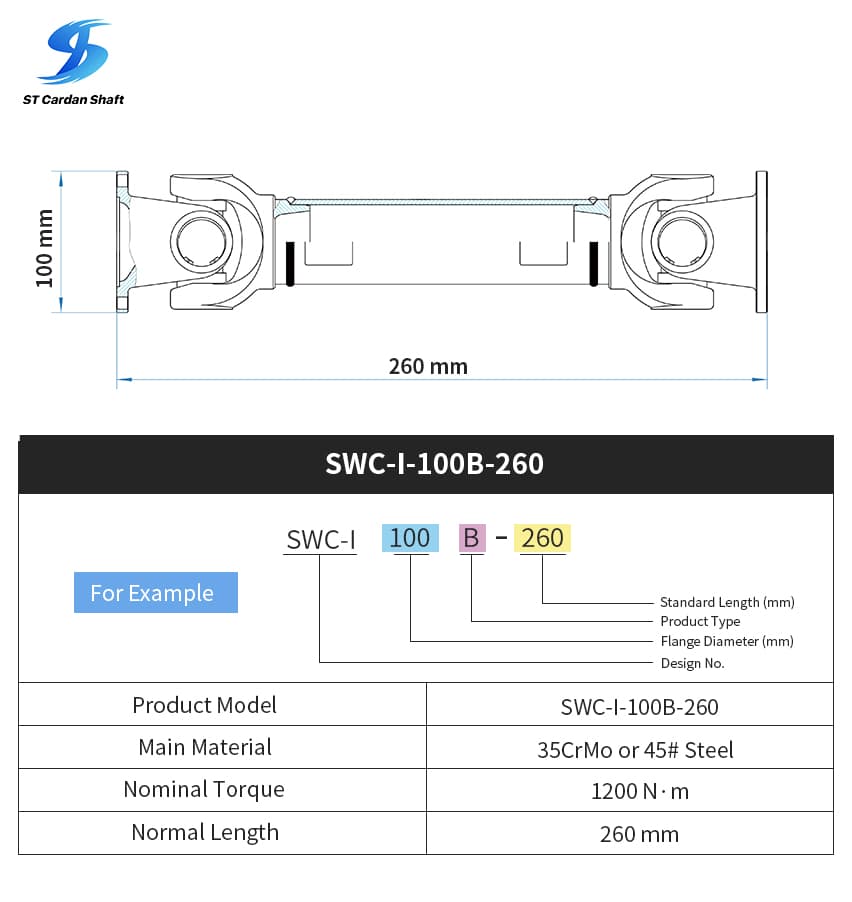

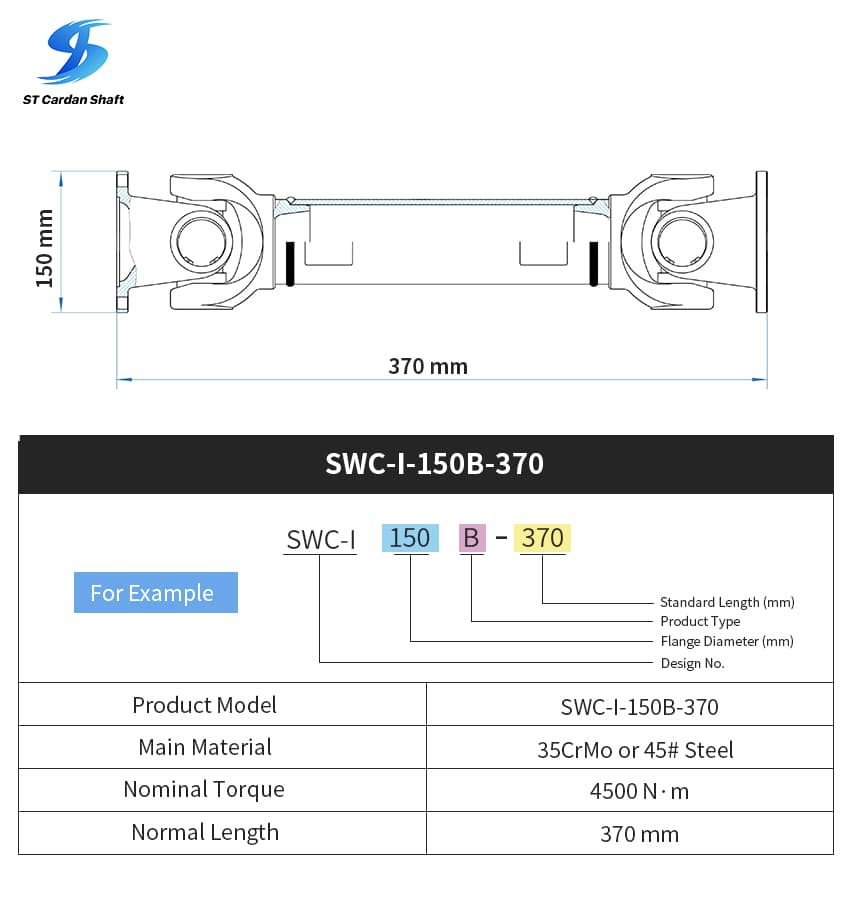

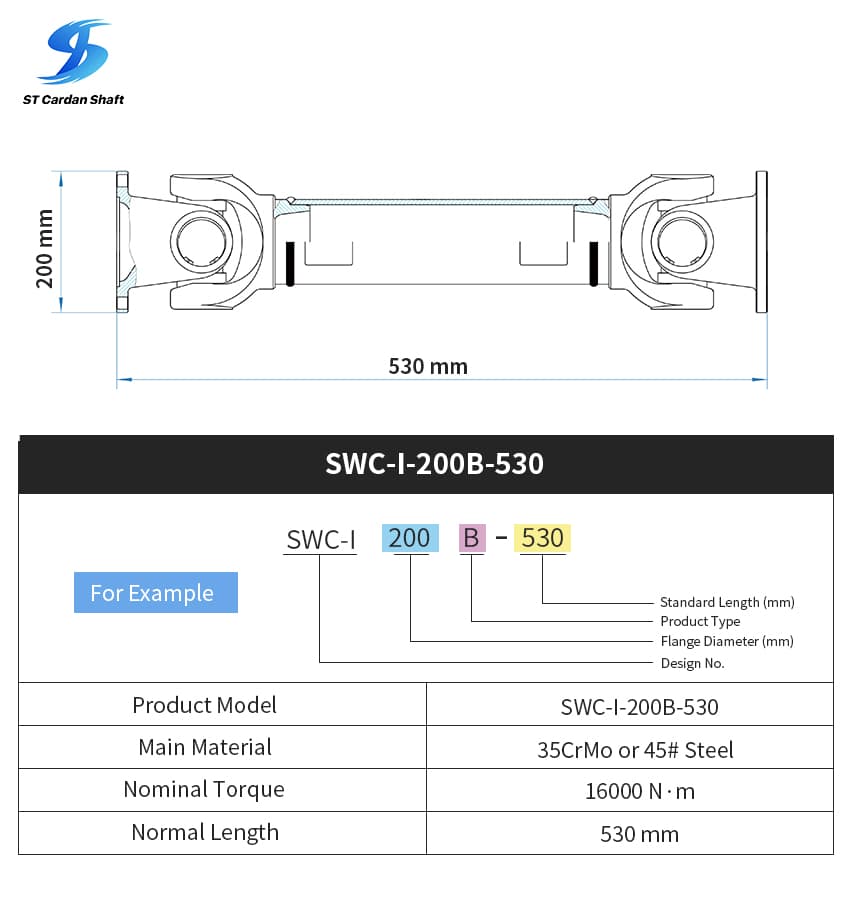

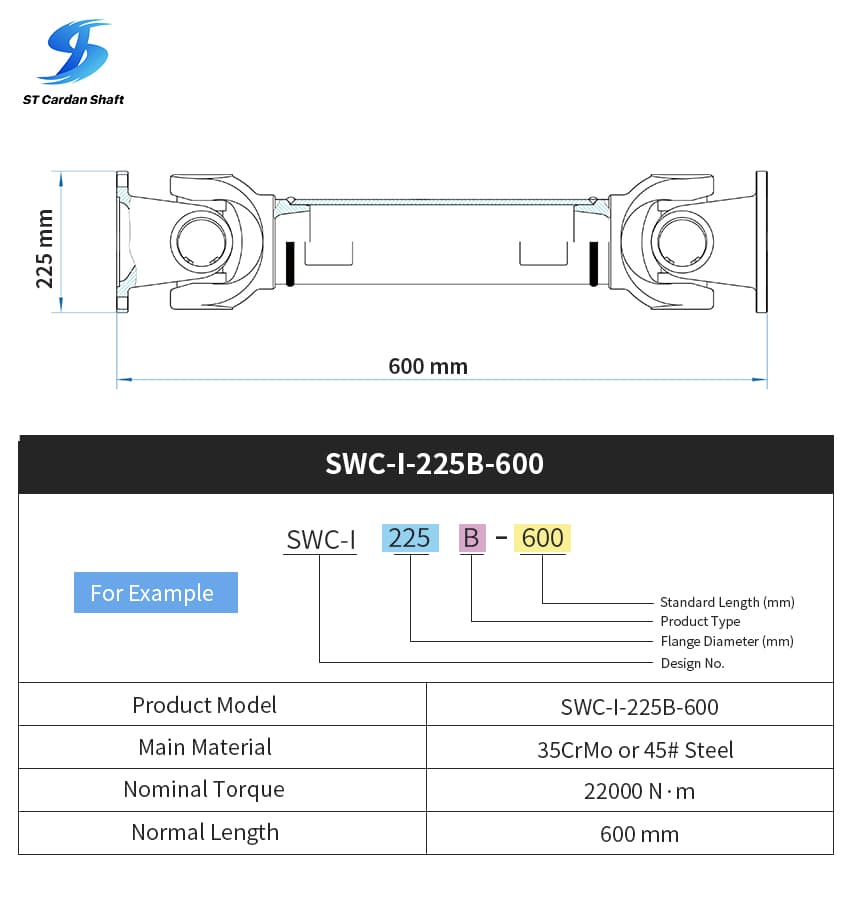

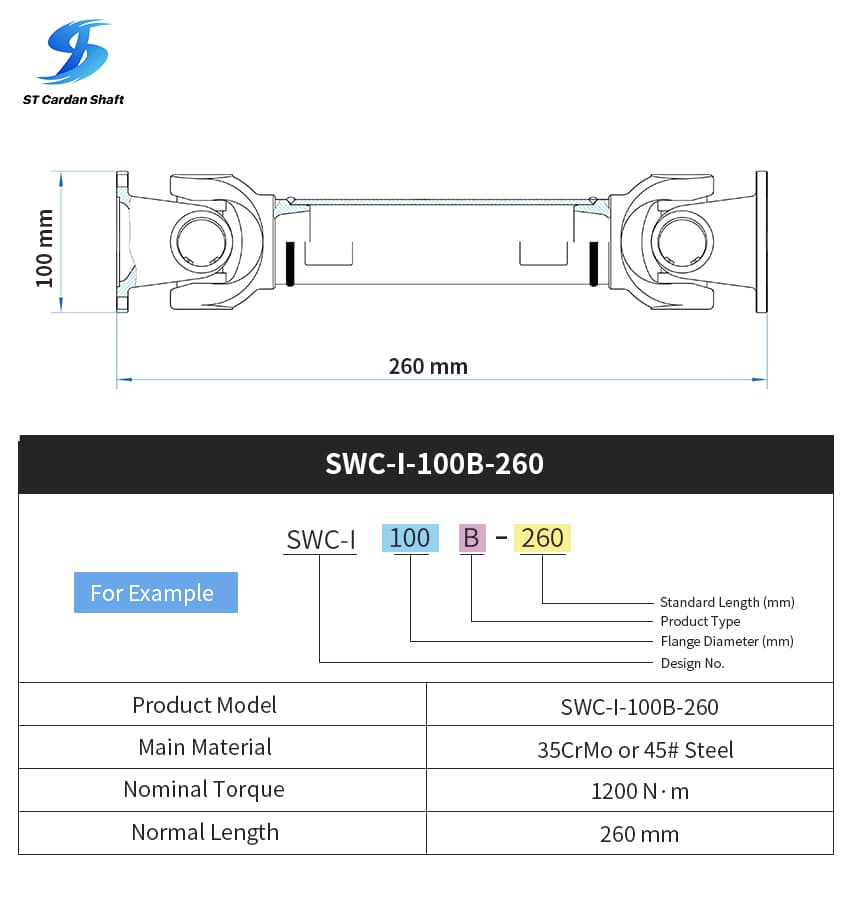

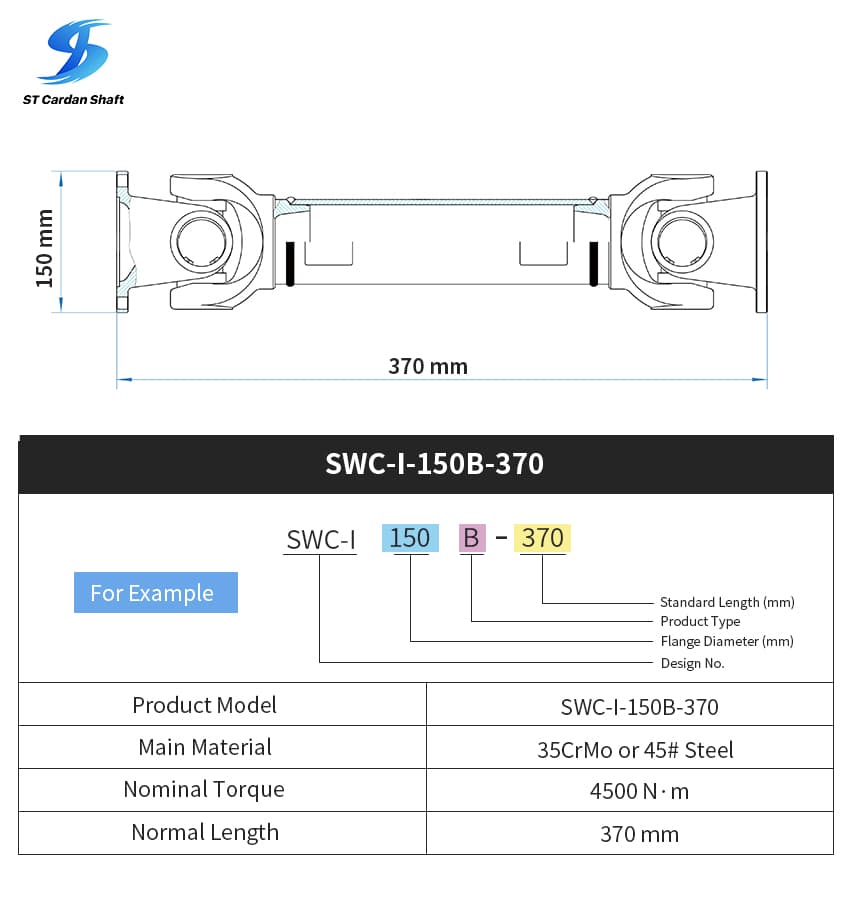

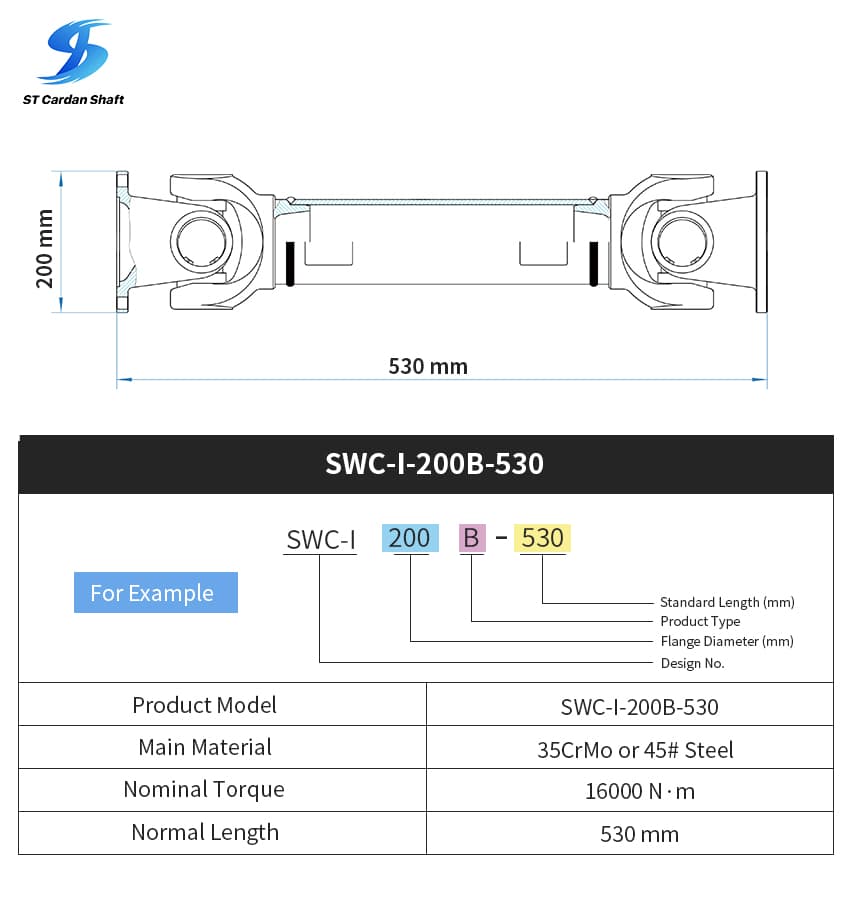

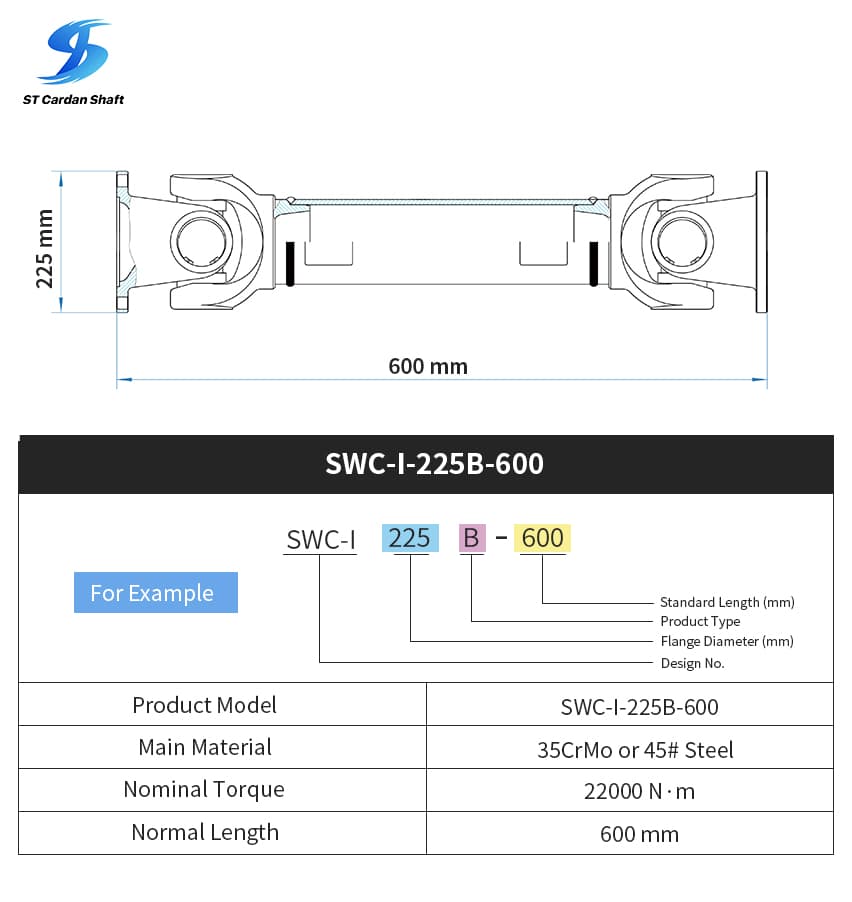

Below you can find the design drawings and detailed product parameters for the Type B Series.

Data Sheet – Light Duty Type B Series:

| Model | SWC-I 58 | SWC-I 65 | SWC-I 75 | SWC-I 90 | SWC-I 100 | SWC-I 120 | SWC-I 150 | SWC-I 180 | SWC-I 200 | SWC-I 225 |

|---|---|---|---|---|---|---|---|---|---|---|

| L | 150 | 175 | 200 | 240 | 260 | 295 | 370 | 430 | 530 | 600 |

| m (kg) | 1.7 | 2.4 | 3.8 | 5.7 | 7.7 | 13.1 | 23 | 28 | 55 | 98 |

| Tn (N·m) | 180 | 240 | 500 | 800 | 1200 | 2300 | 4500 | 8400 | 16000 | 22000 |

| Tf (N·m) | 90 | 120 | 250 | 400 | 600 | 1150 | 2250 | 4200 | 8000 | 11000 |

| β (°) | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 25 | 25 | 25 |

| D | 52 | 63 | 72 | 92 | 100 | 112 | 142 | 154 | 187 | 204 |

| Df | 58 | 65 | 75 | 90 | 100 | 120 | 150 | 180 | 200 | 225 |

| D1 | 47 | 52 | 62 | 74.5 | 84 | 101.5 | 130 | 155.5 | 170 | 196 |

| D2 (H9) | 30 | 35 | 42 | 47 | 57 | 75 | 90 | 110 | 125 | 140 |

| D3* θ | 45×3 | 45×3 | 45×3 | 63.5×2.5 | 63.5×2.5 | 76×4 | 90×3 | 92×6.5 | 120×6 | 140×9 |

| Lm | 32 | 39 | 45 | 52 | 55 | 63 | 78 | 90 | 110 | 120 |

| k | 3.5 | 4.5 | 5.5 | 6 | 8 | 8 | 10 | 14 | 17 | 18 |

| t | 1.5 | 1.7 | 2 | 2.5 | 2.5 | 2.5 | 3 | 4 | 4 | 5 |

| n | 4 | 4 | 6 | 4 | 6 | 8 | 8 | 8 | 8 | 8 |

| d | 5.1 | 6.5 | 6.5 | 8.5 | 8.5 | 10.5 | 13 | 15 | 17 | 17 |

| ML (kg) | 0.14 | 0.16 | 0.38 | 0.38 | 0.53 | 0.53 | 0.87 | 0.87 | 1.65 | 2.14 |

| (Flange Bolt) | ||||||||||

| Size | M5 | M6 | M6 | M8 | M8 | M10 | M12 | M14 | M16 | M16 |

| Tightening torque (N·m) | 7 | 13 | 13 | 32 | 32 | 64 | 110 | 180 | 270 | 270 |

Key Product Features:

● Rigid welded structure – ensures maximum stability and continuous torque transfer in fixed-shaft installations.

● No length compensation – designed for systems with precise shaft alignment, minimizing energy loss during transmission.

● Broad capacity range – 150–22000 N·m torque and 58–225 mm flange diameter, available with custom shaft lengths to suit your setup.

● Flexible customization – one-piece minimum order, with adjustable length, configuration, and mounting options.

● Custom flange connections – available with four adapter choices: bolt hole, face key, integral face pad, or hirth section, tailored on request.