ST Cardan Shaft

Flanged Rigid Shaft - Type C Series

The Light Duty Type C Series adopts a flanged rigid connection, designed for applications that require precise alignment and steady torque delivery. It is widely used in light industrial transmission systems, printing machines, and packaging lines where compact installation and consistent performance are essential.

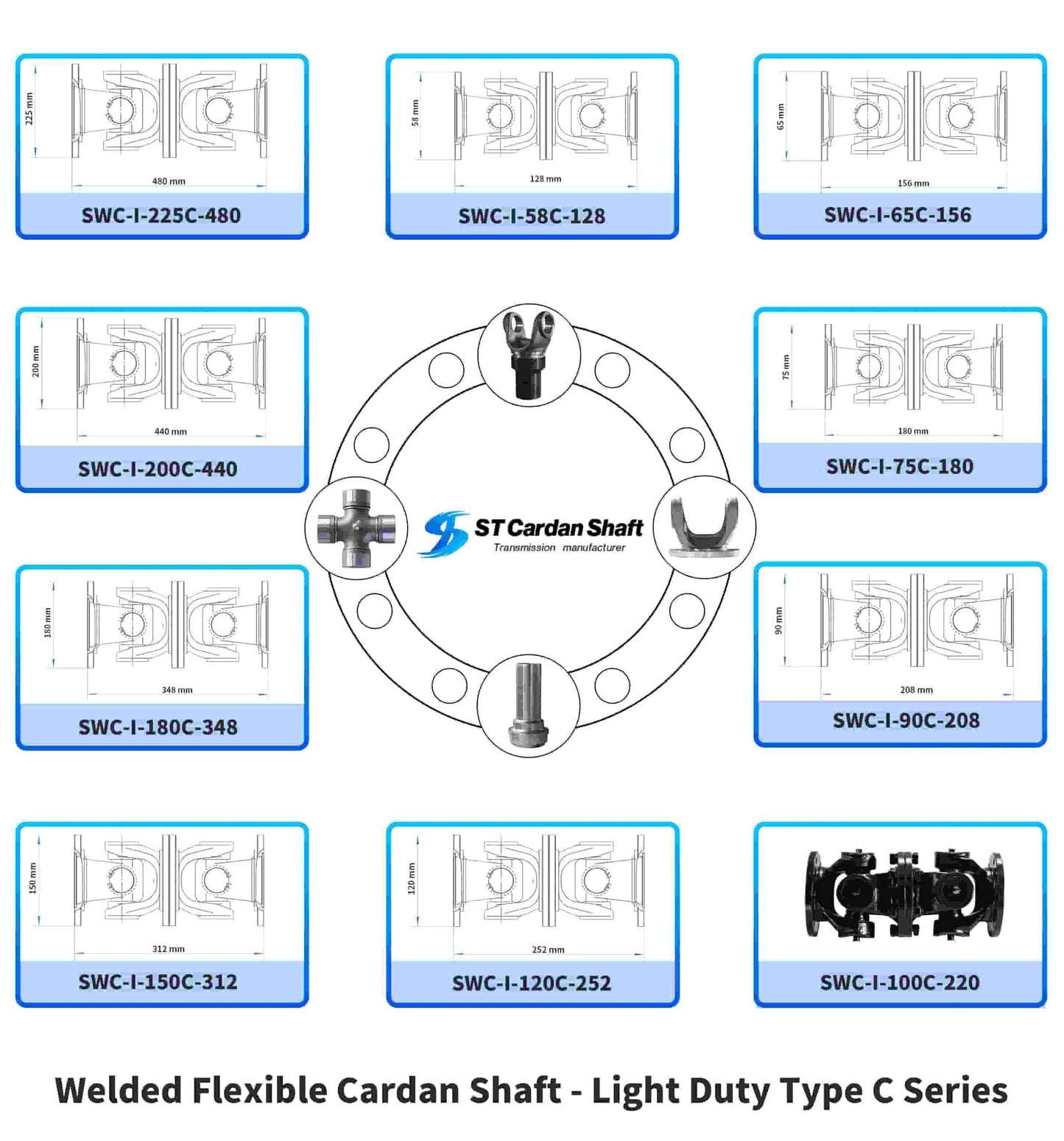

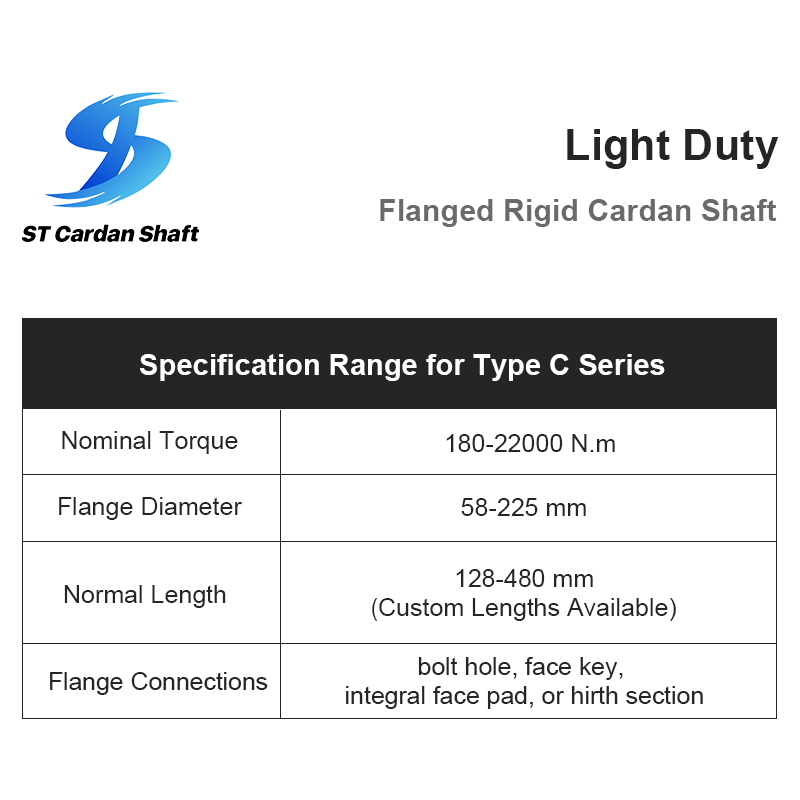

This series includes 10 models with the following specifications:

● Nominal torque: 150–22000 N·m

● Flanged diameter: 58–225 mm

● Standard length: 128–400 mm (custom lengths available)

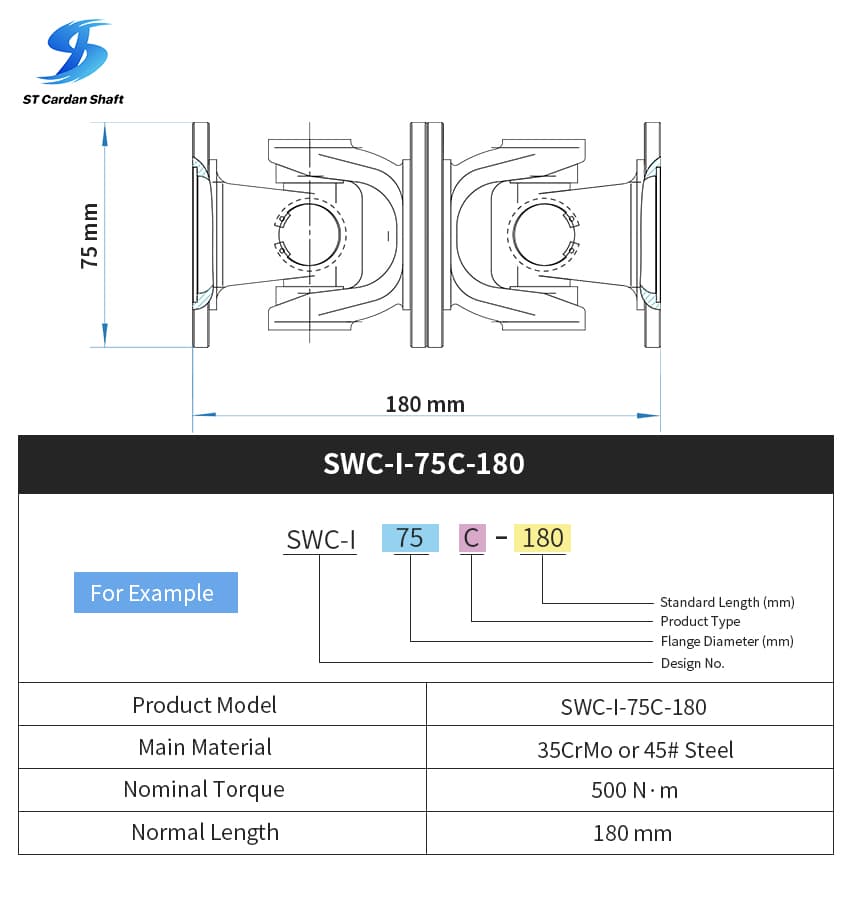

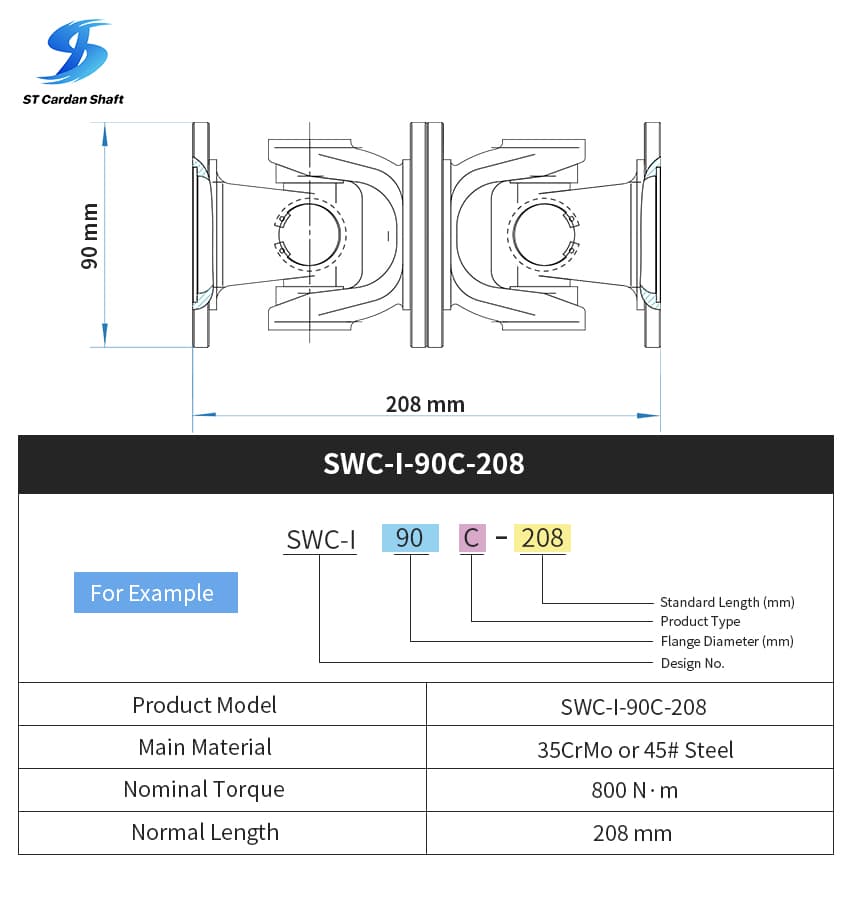

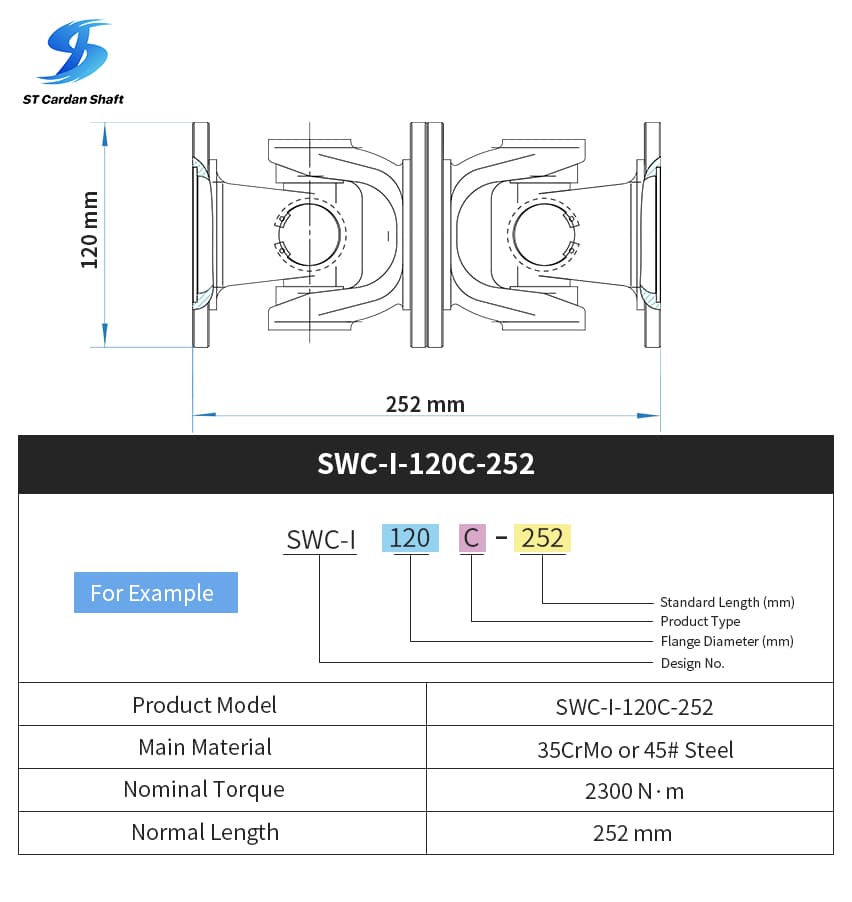

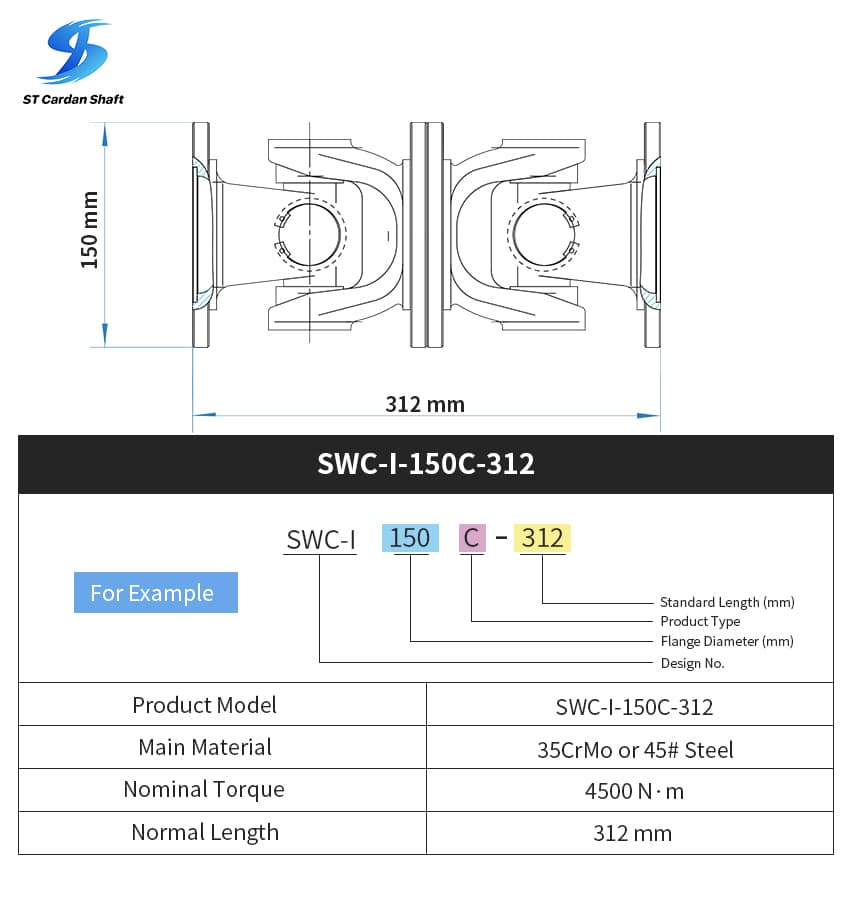

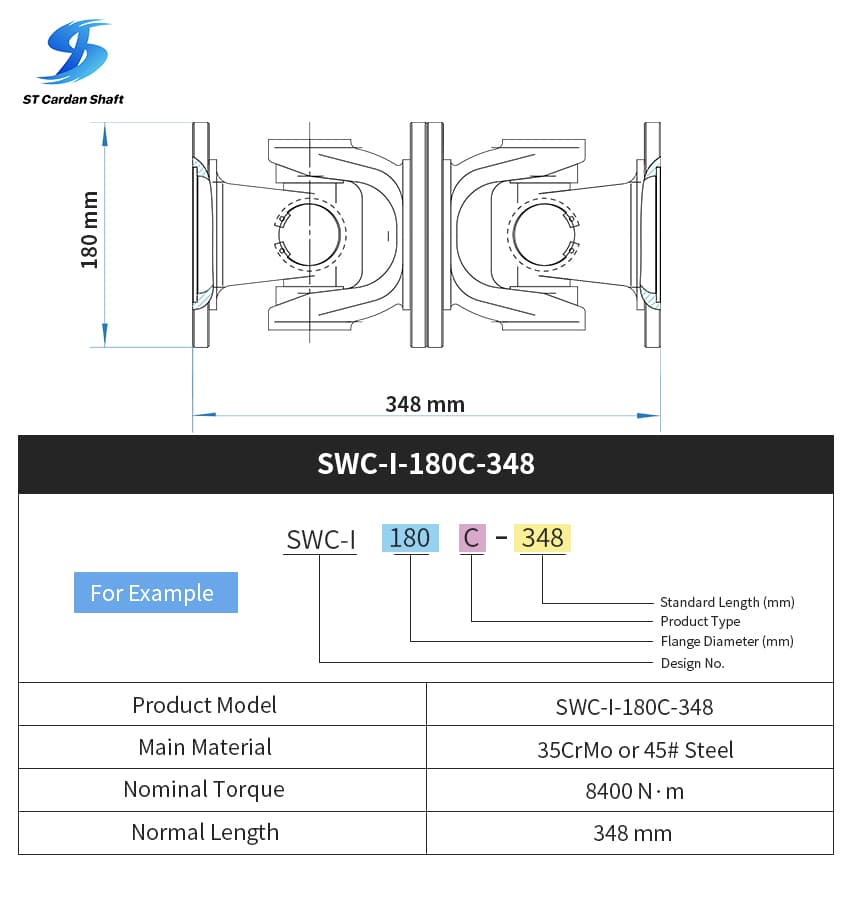

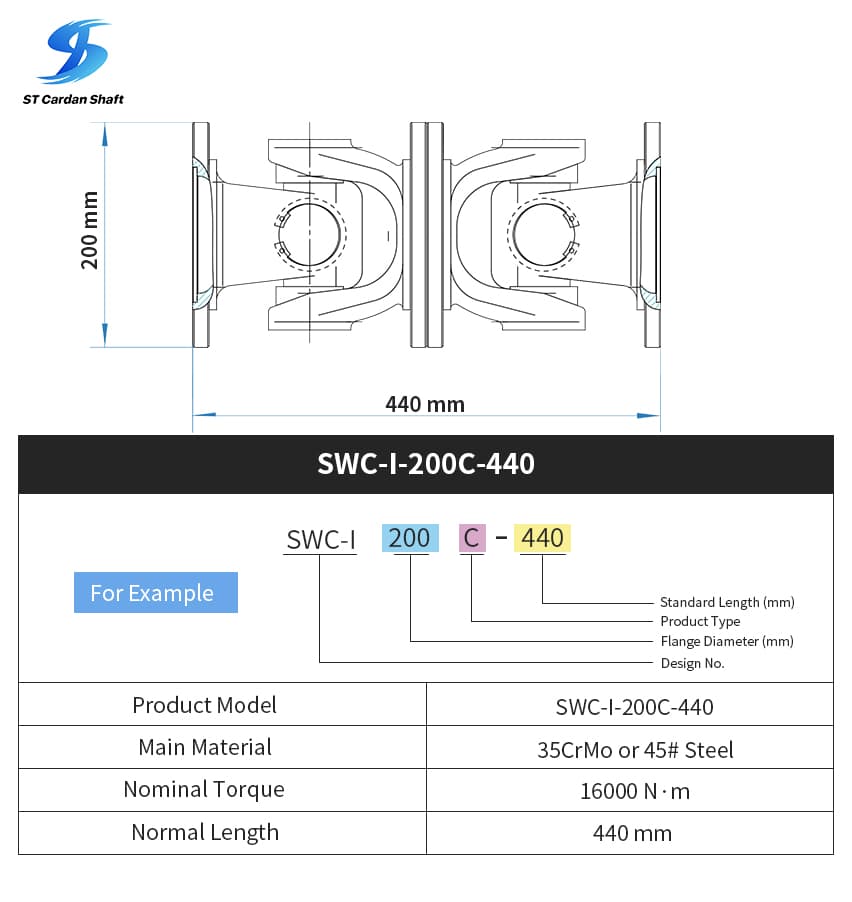

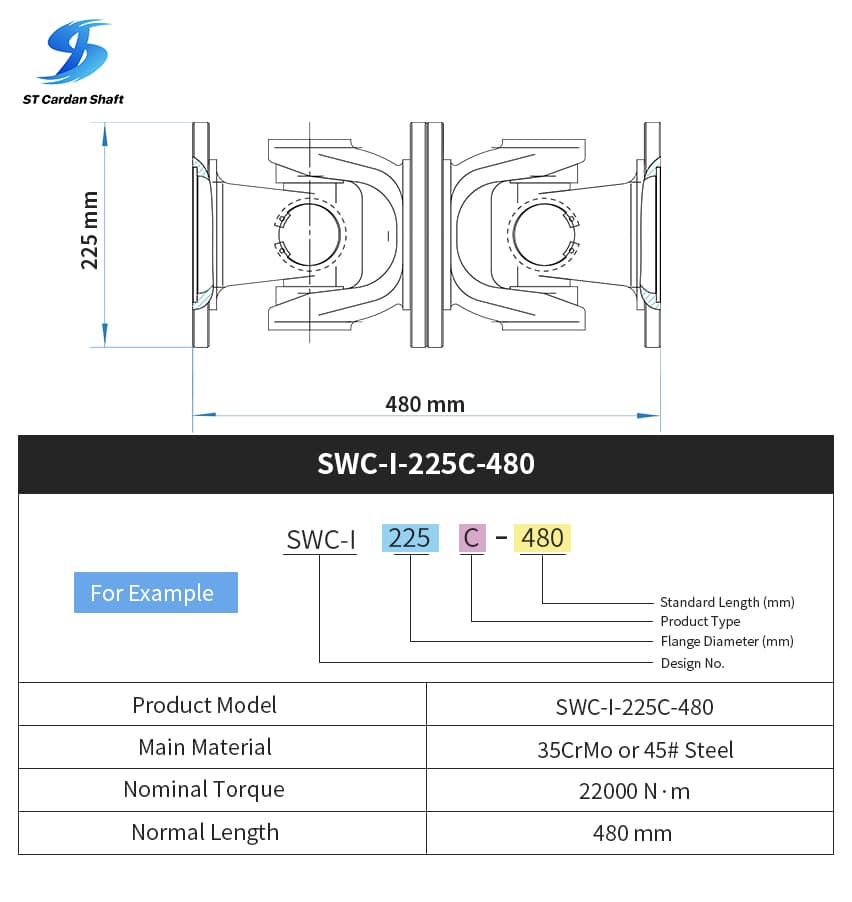

Below you can find the design drawings and detailed product parameters for the Type C Series.

Design and Data Sheet – Light Duty Type C Series:

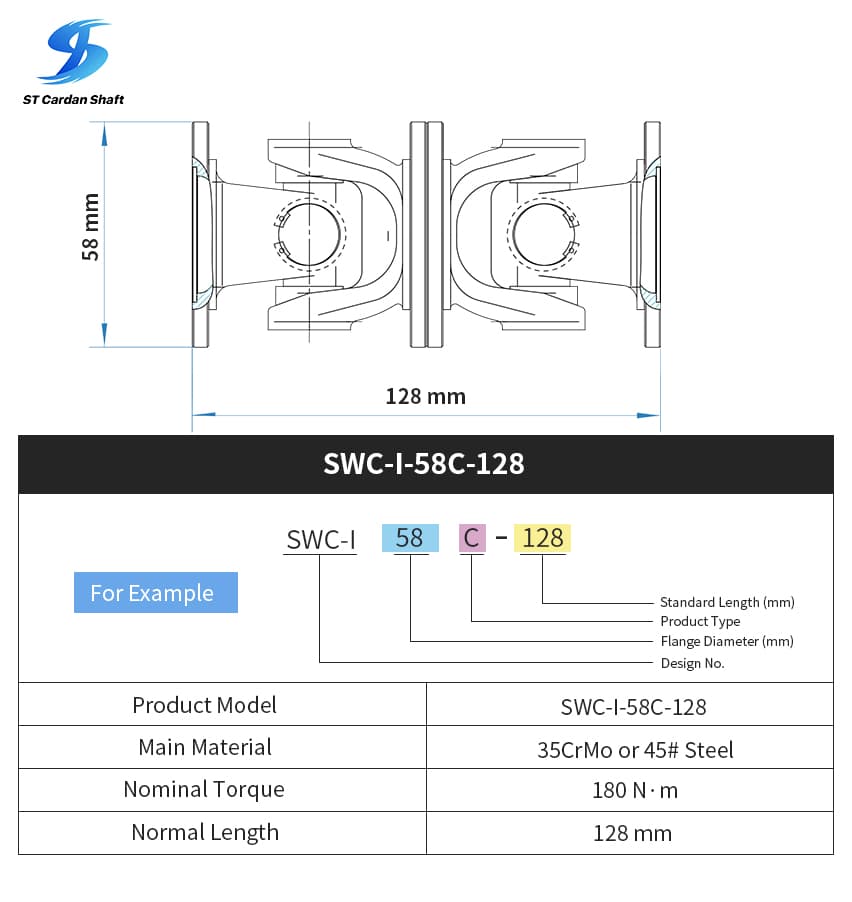

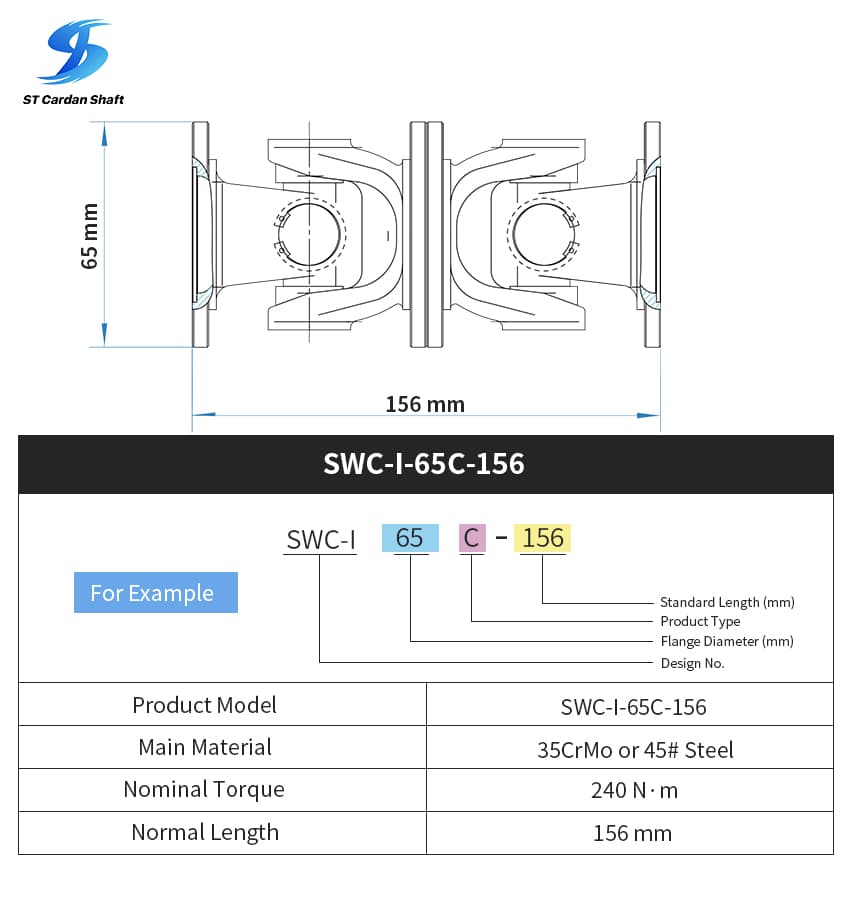

| Model | SWC-I 58 | SWC-I 65 | SWC-I 75 | SWC-I 90 | SWC-I 100 | SWC-I 120 | SWC-I 150 | SWC-I 180 | SWC-I 200 | SWC-I 225 |

|---|---|---|---|---|---|---|---|---|---|---|

| L | 128 | 156 | 180 | 208 | 220 | 252 | 312 | 348 | 440 | 480 |

| m (kg) | 1.3 | 1.95 | 3.1 | 5 | 7 | 12.3 | 22 | 30 | 56 | 96 |

| Tn (N·m) | 180 | 240 | 500 | 800 | 1200 | 2300 | 4500 | 8400 | 16000 | 22000 |

| Tf (N·m) | 90 | 120 | 250 | 400 | 600 | 1150 | 2250 | 4200 | 8000 | 11000 |

| β (°) | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 25 | 25 | 25 |

| D | 52 | 63 | 72 | 92 | 100 | 112 | 142 | 154 | 187 | 204 |

| Df | 58 | 65 | 75 | 90 | 100 | 120 | 150 | 180 | 200 | 225 |

| D1 | 47 | 52 | 62 | 74.5 | 84 | 101.5 | 130 | 155.5 | 170 | 196 |

| D2 (H9) | 30 | 35 | 42 | 47 | 57 | 75 | 90 | 110 | 125 | 140 |

| D3* θ | 45*3 | 45*3 | 45*3 | 63.5*2.5 | 63.5*2.5 | 76*4 | 90*3 | 92*6.5 | 120*6 | 140*9 |

| Lm | 32 | 39 | 45 | 52 | 55 | 63 | 78 | 90 | 110 | 120 |

| k | 3.5 | 4.5 | 5.5 | 6 | 8 | 8 | 10 | 14 | 17 | 18 |

| t | 1.5 | 1.7 | 2 | 2.5 | 2.5 | 2.5 | 3 | 4 | 4 | 5 |

| n | 4 | 4 | 6 | 4 | 6 | 8 | 8 | 8 | 8 | 8 |

| d | 5.1 | 6.5 | 6.5 | 8.5 | 8.5 | 10.5 | 13 | 15 | 17 | 17 |

| ML (kg) | 0.14 | 0.16 | 0.38 | 0.38 | 0.53 | 0.53 | 0.87 | 0.87 | 1.65 | 2.14 |

| Flange Bolt | ||||||||||

| Size | M5 | M6 | M6 | M8 | M8 | M10 | M12 | M14 | M16 | M16 |

| Tightening torque (N·m) | 7 | 13 | 13 | 32 | 32 | 64 | 110 | 180 | 270 | 270 |

Key Product Features:

● Flanged rigid design – provides secure shaft-to-shaft connection for stable torque transfer.

● Compact build – shorter standard length (128–400 mm) makes it ideal for space-limited installations.

● Reliable performance – covers 150–22000 N·m torque range with 58–225 mm flange diameter for light-duty applications.

● Custom-built options – available from one piece, with tailored length, flange type, and configuration to fit specific machinery.

● Multiple flange choices – four adapter options: bolt hole, face key, integral face pad, or hirth section, all customizable on request.