ST Cardan Shaft

Flexible Flanged Shaft – Type E Series

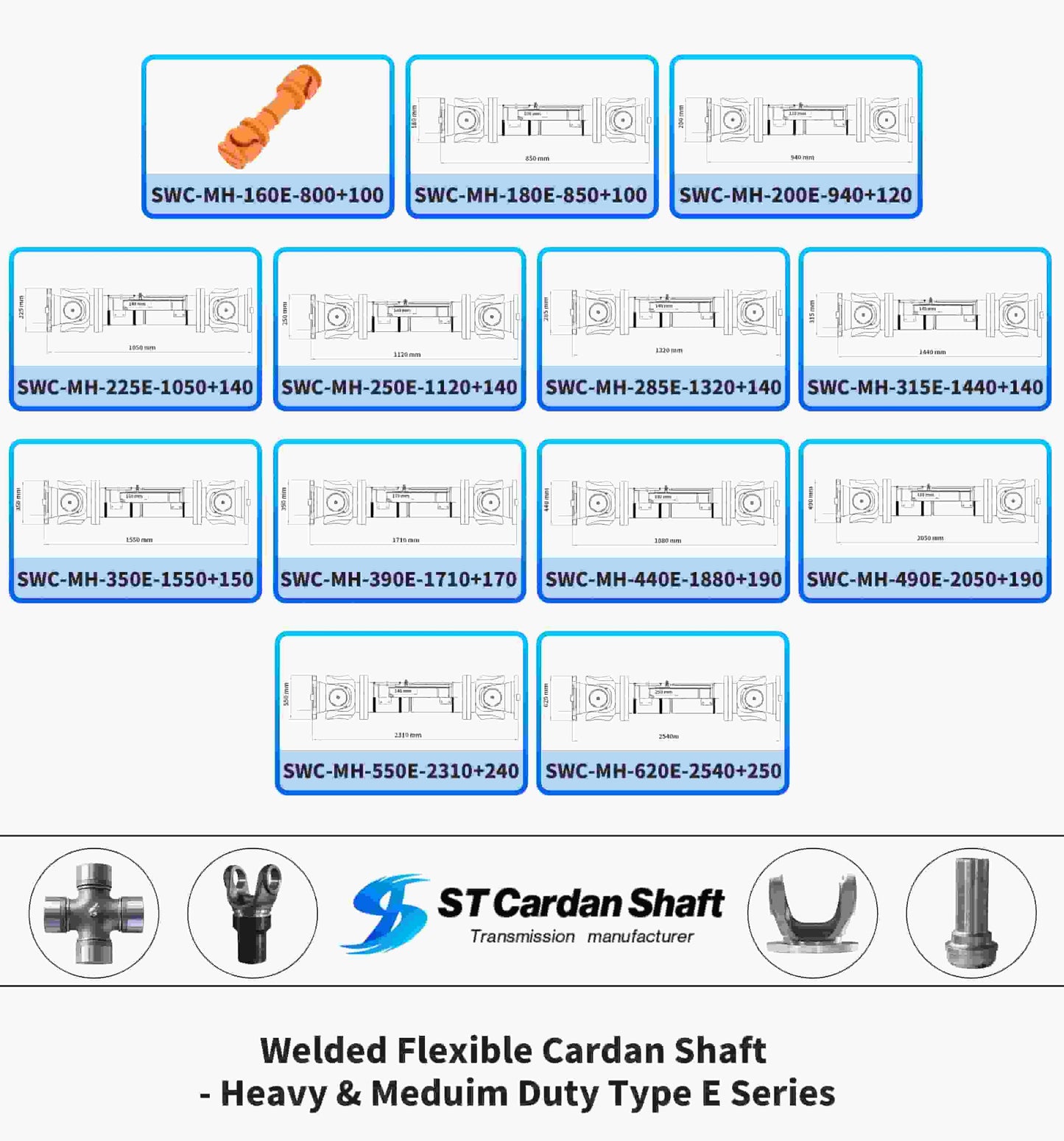

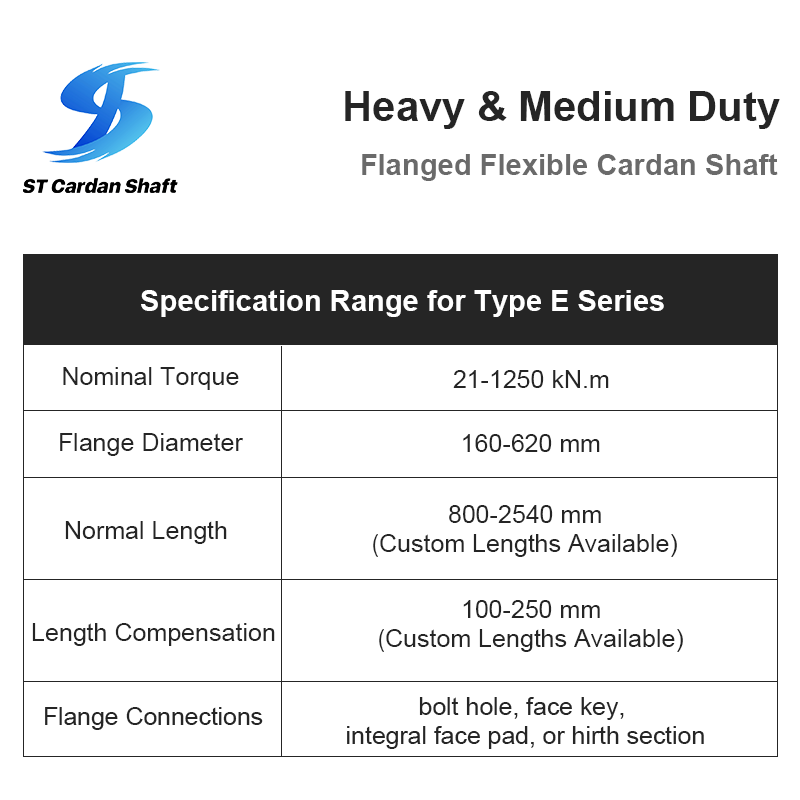

The Heavy & Medium Duty Type E Series features a flexible flanged connection that provides both high torque capacity and misalignment compensation. This design makes it ideal for heavy-duty machinery such as mixers, ball mills, and roller tables, where stable performance and vibration reduction are essential.

This series includes multiple models with the following specifications:

● Nominal torque: 21–1,250 kN·m

● Flanged diameter: 160–620 mm

● Length range: 520–1,720 mm (custom lengths available)

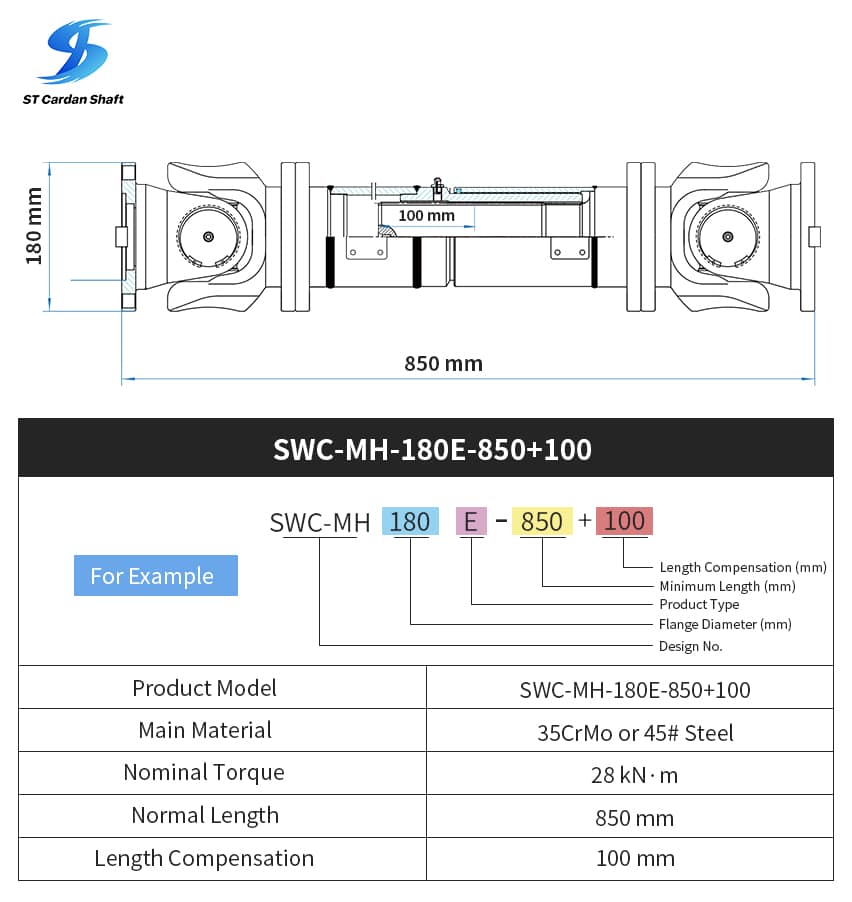

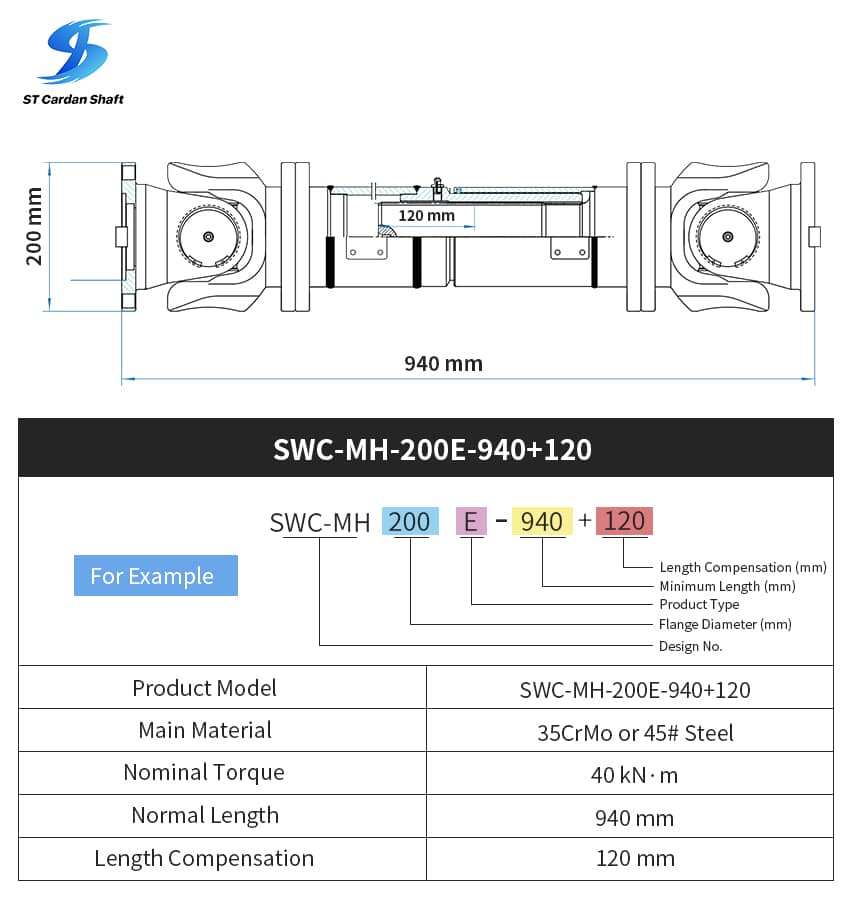

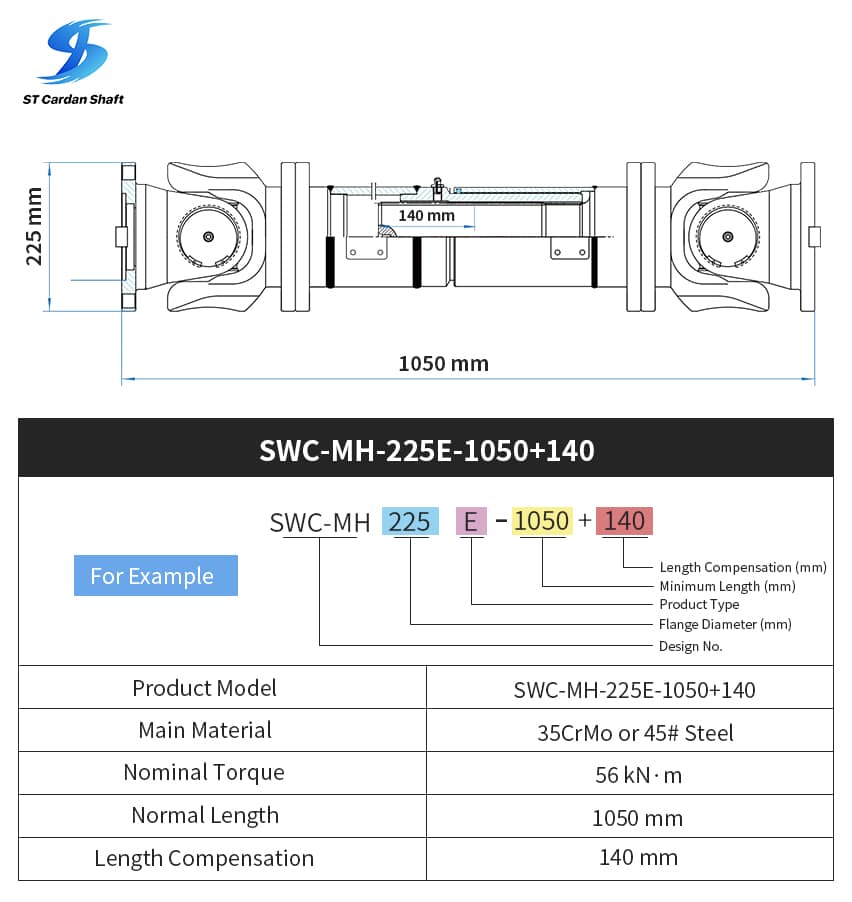

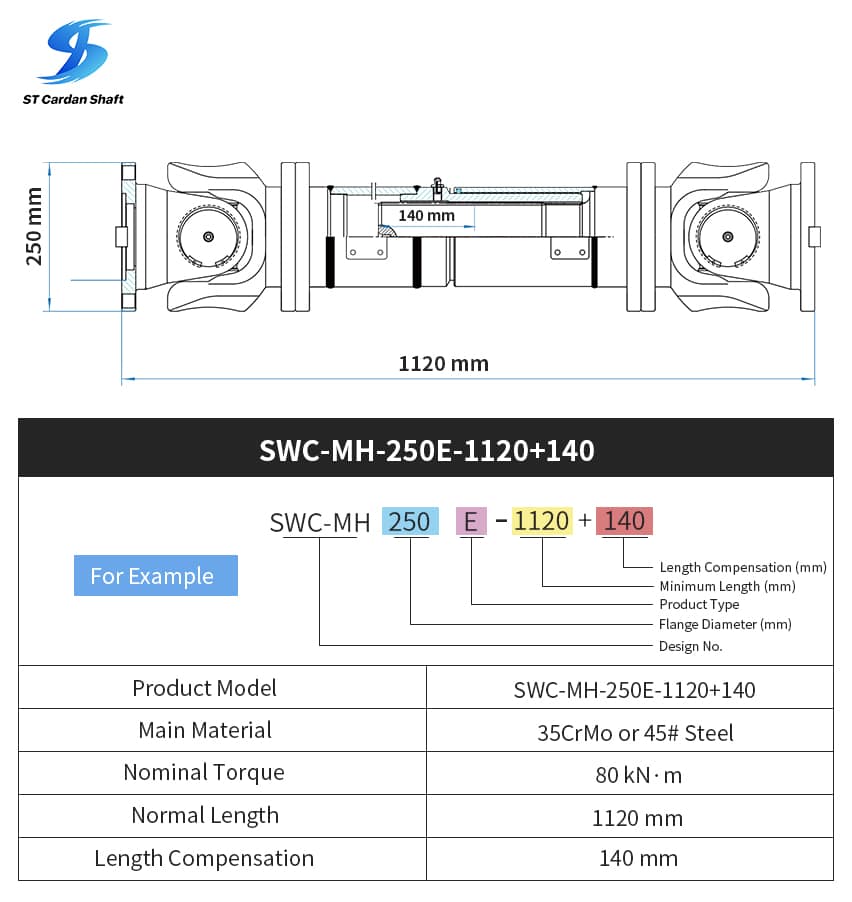

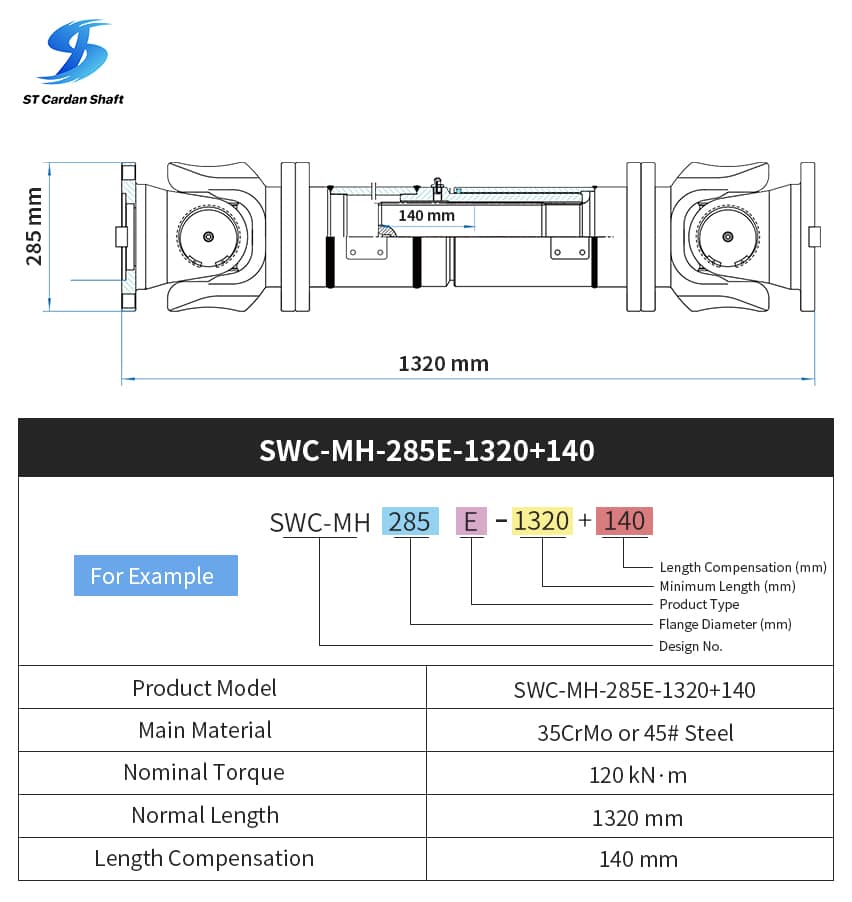

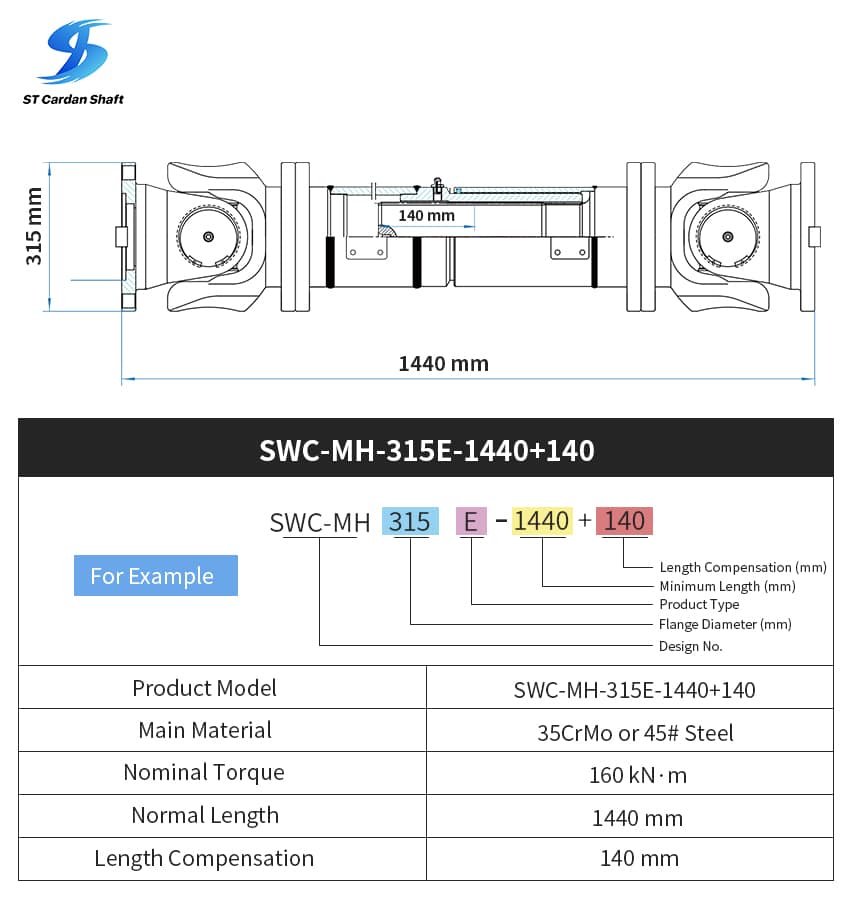

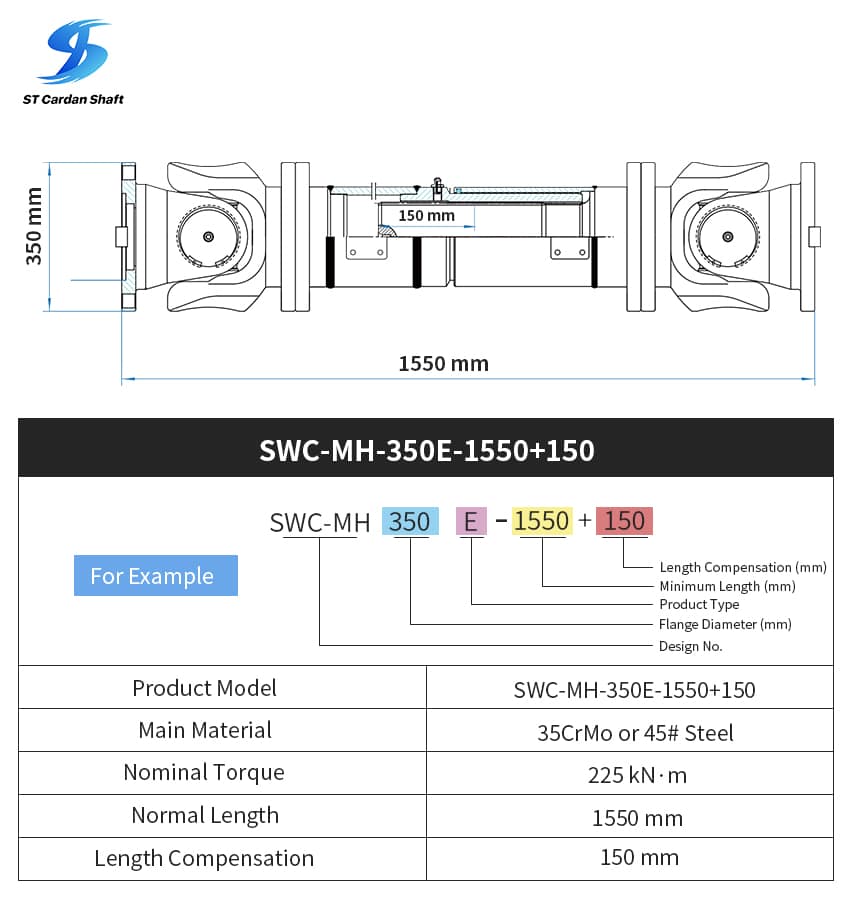

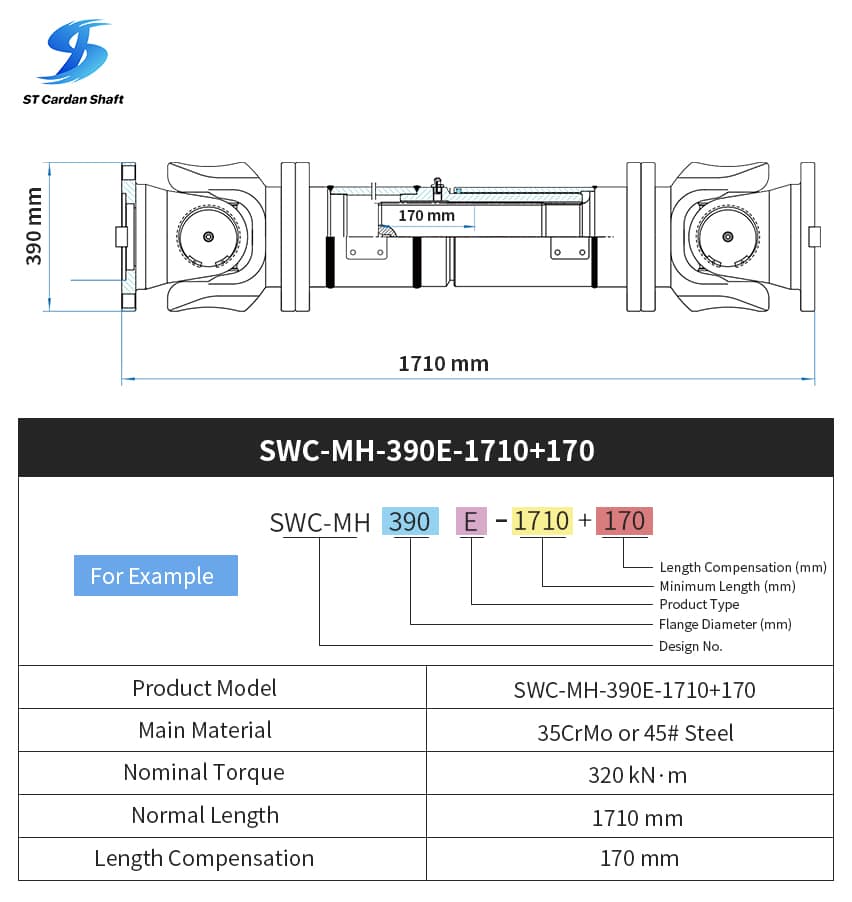

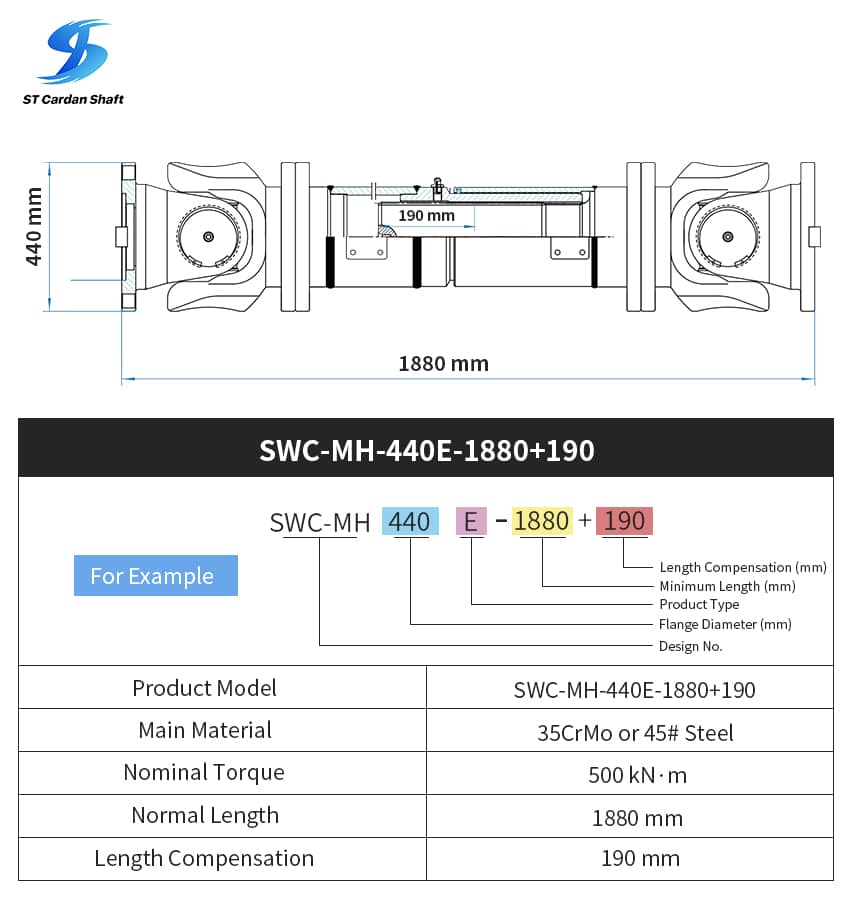

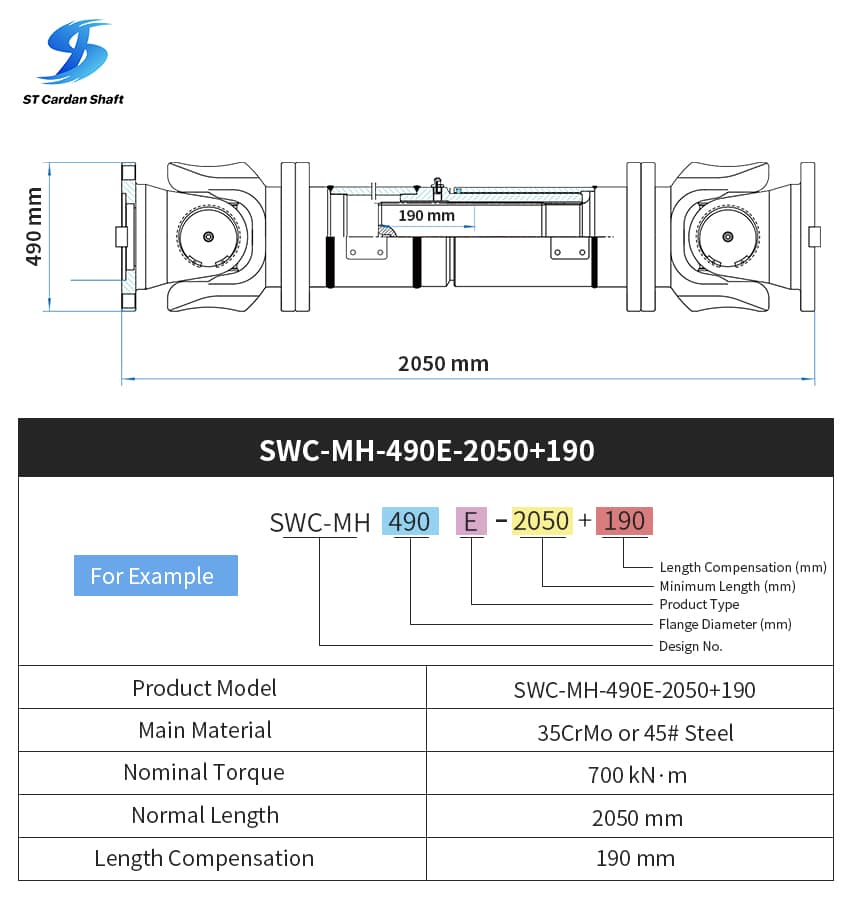

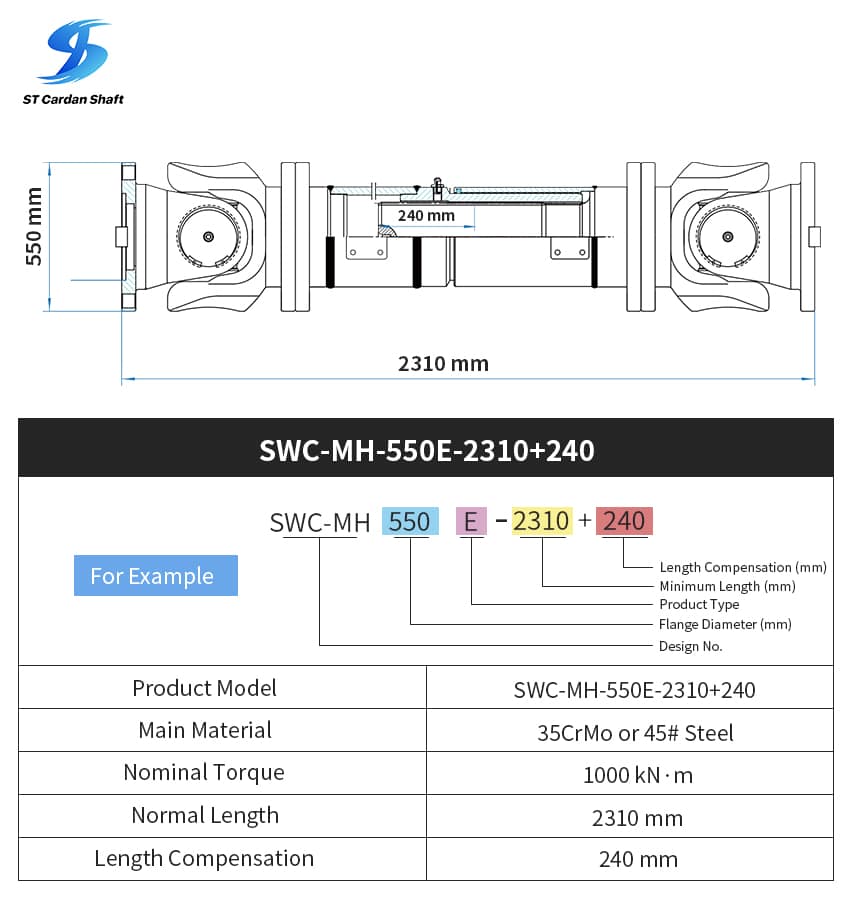

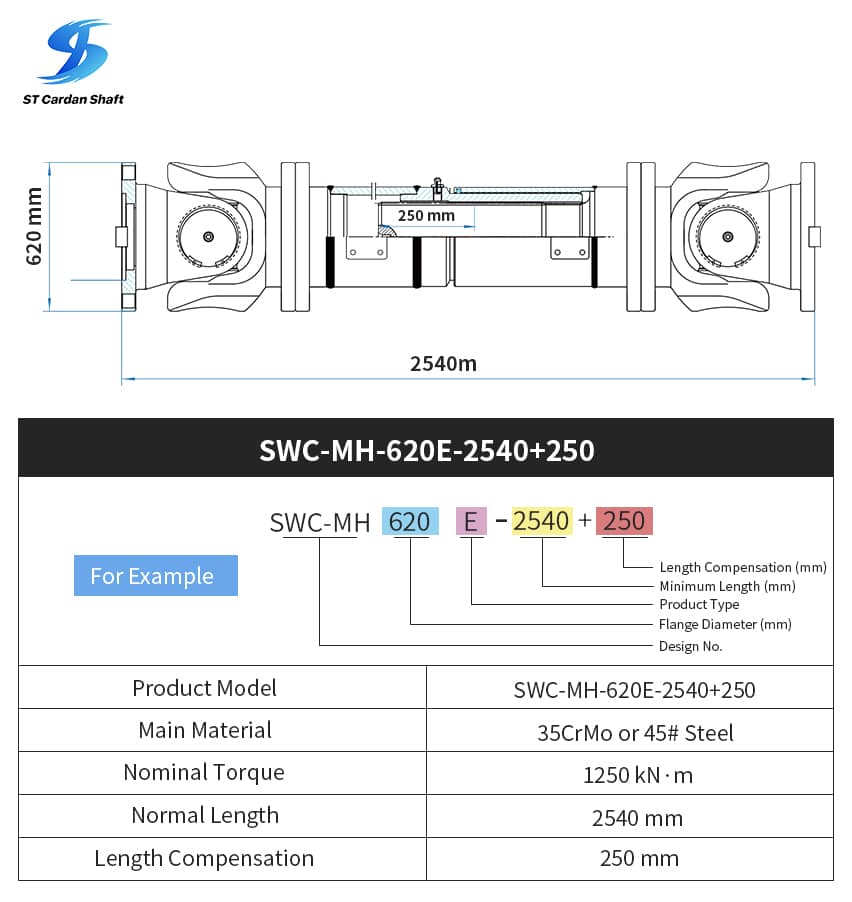

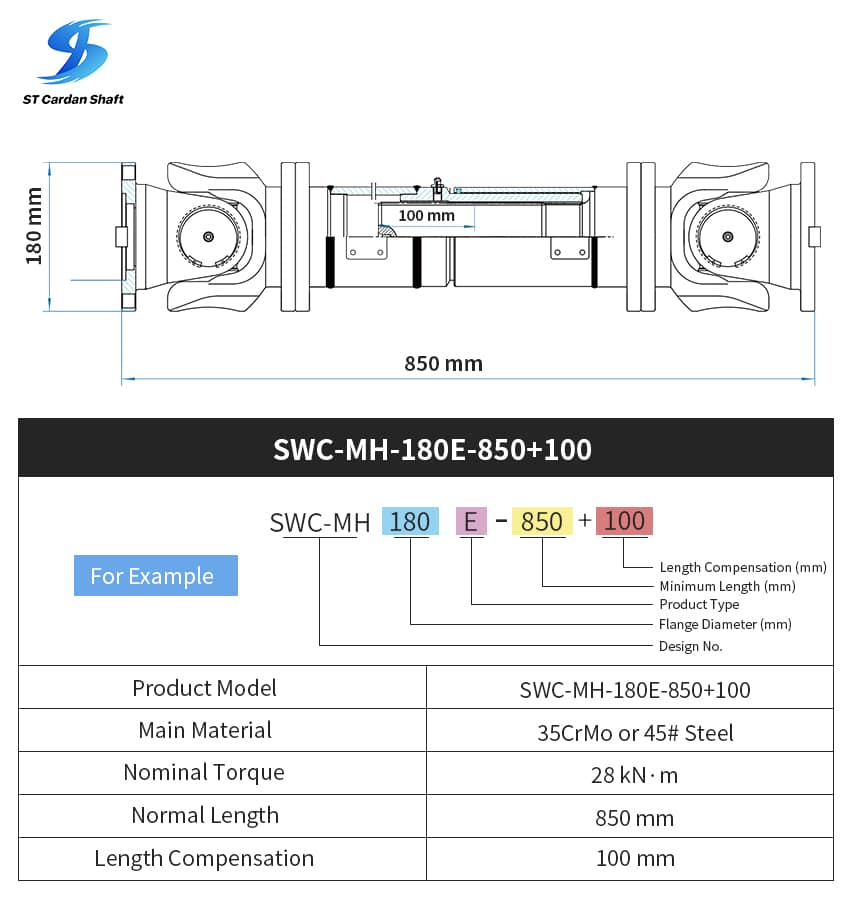

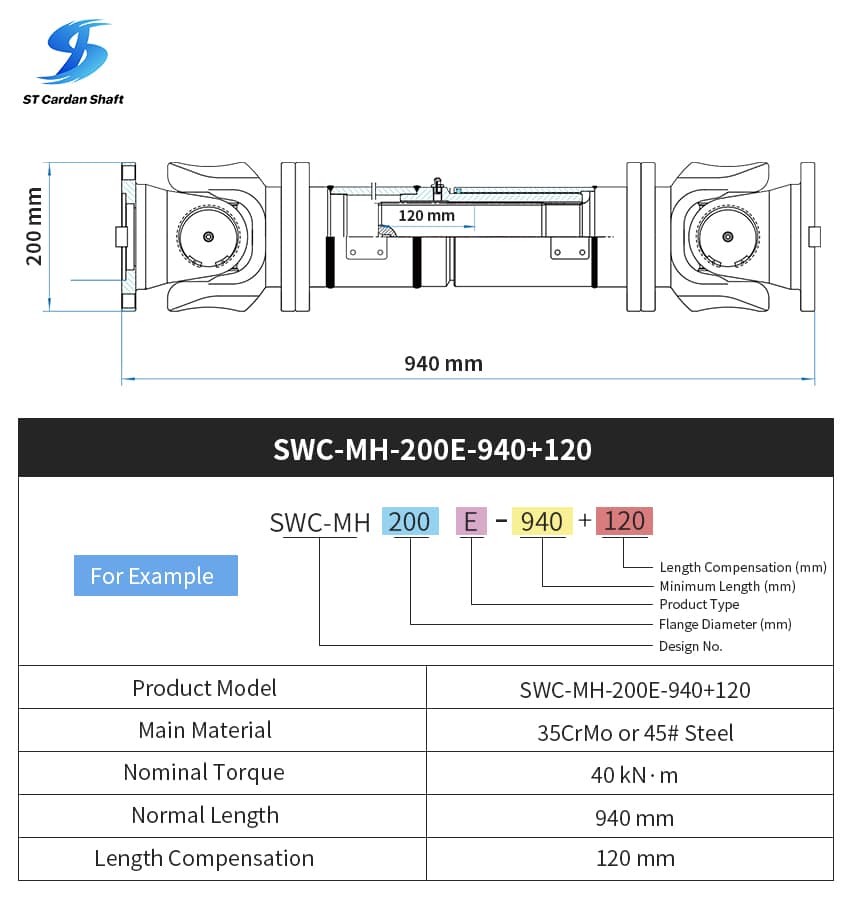

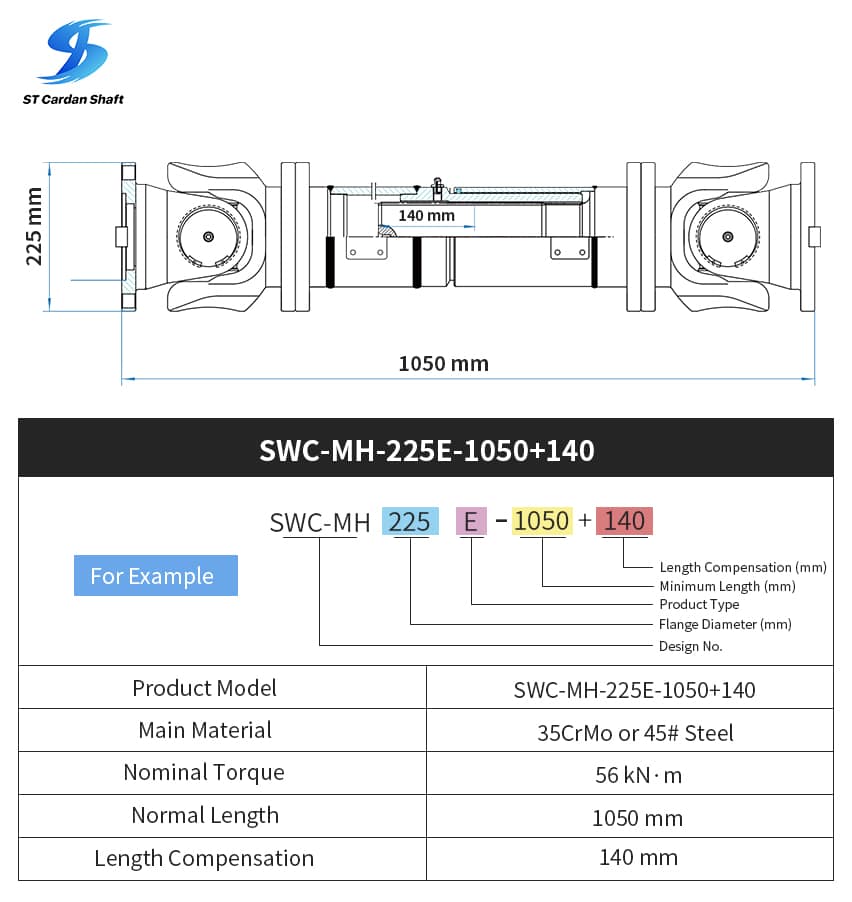

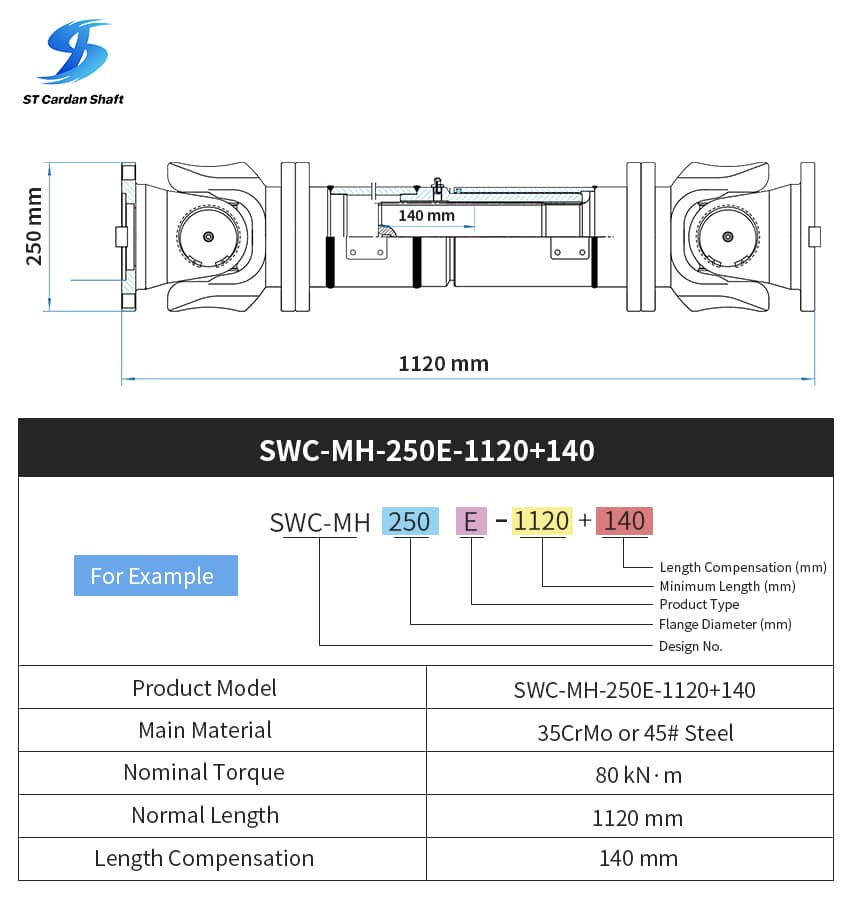

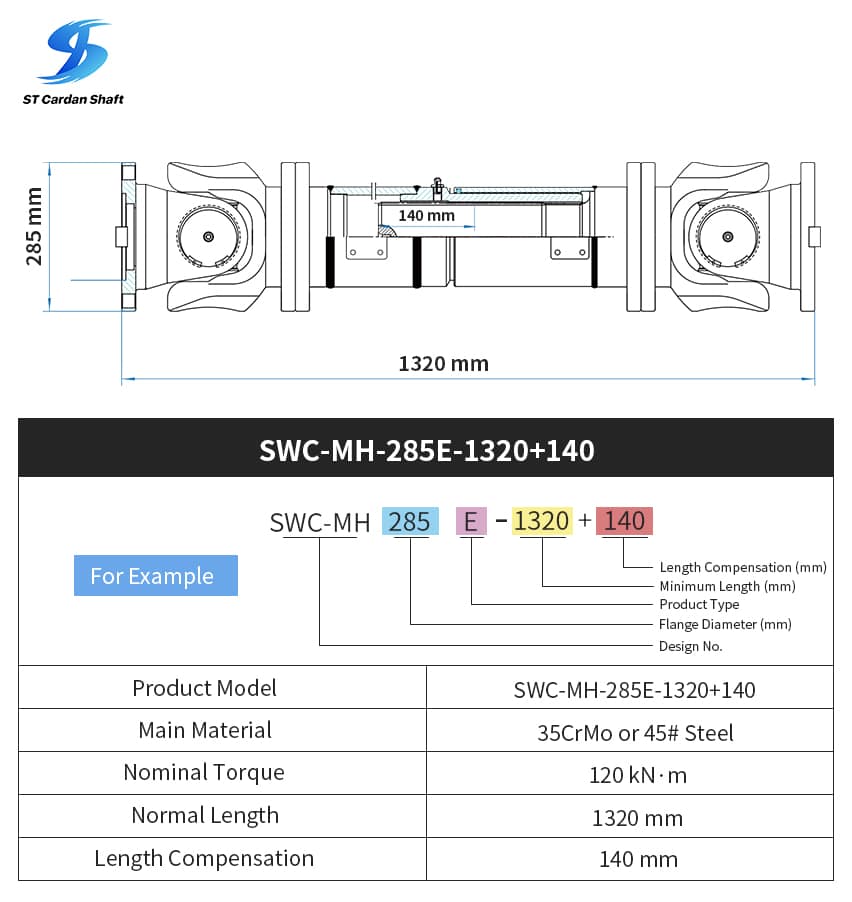

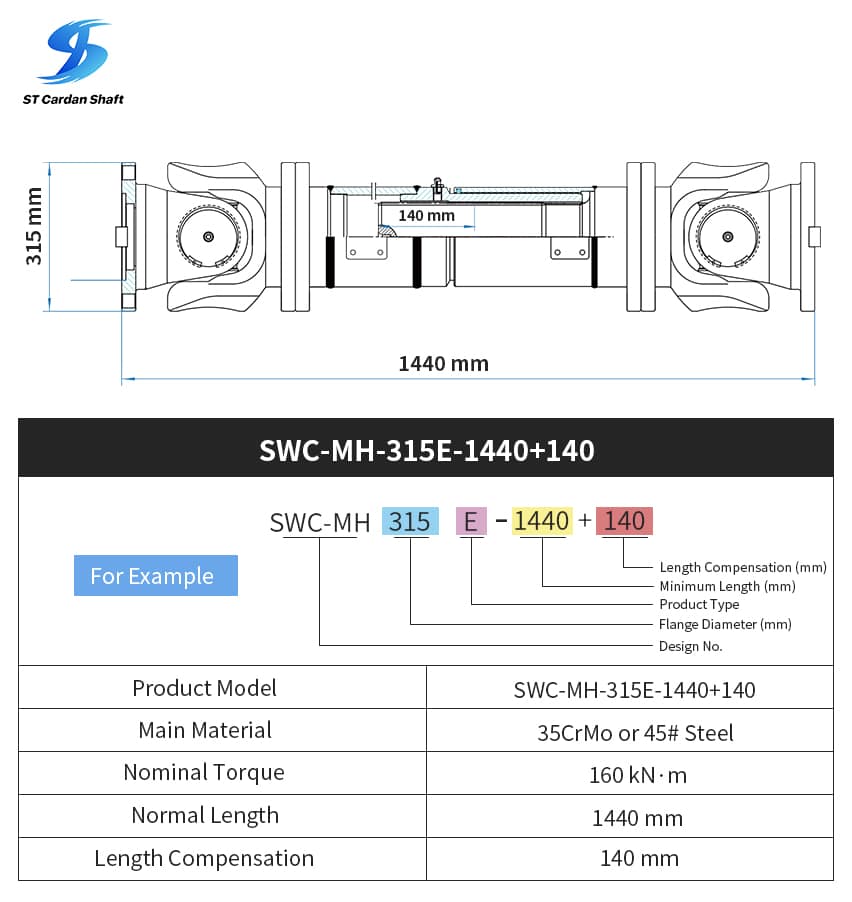

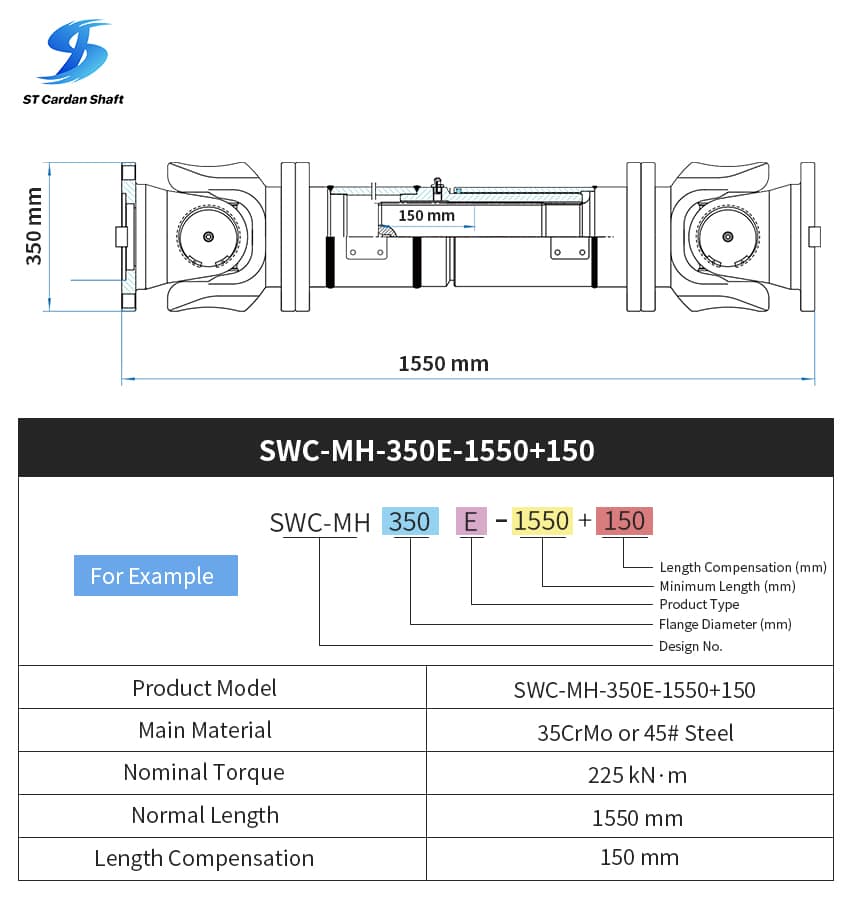

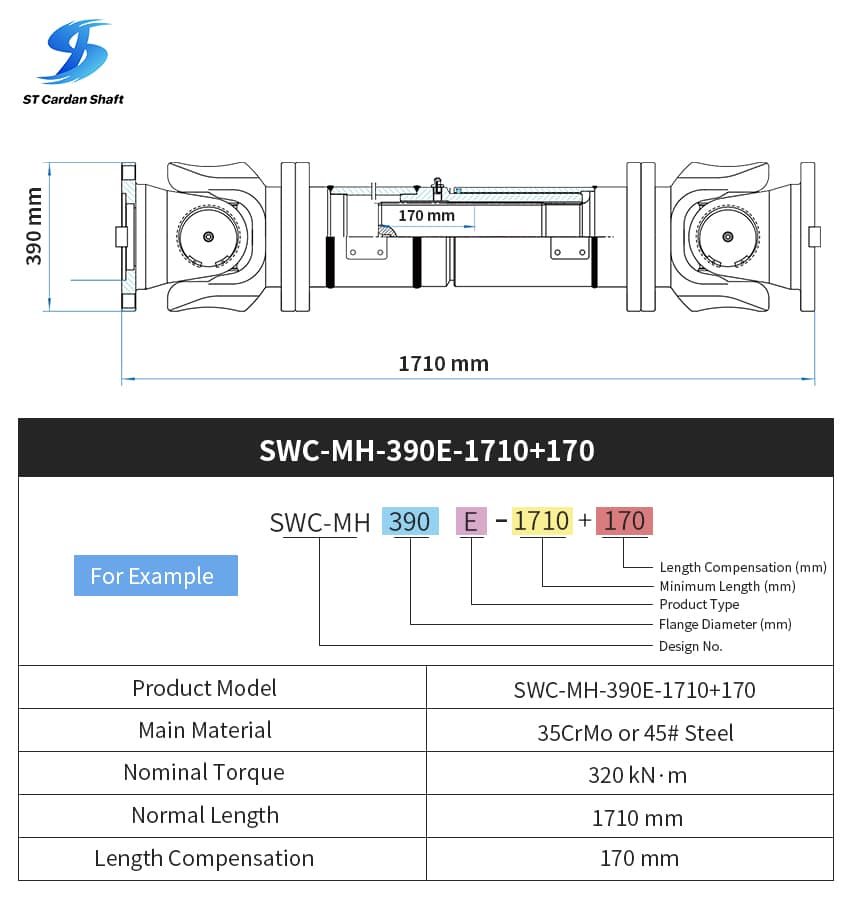

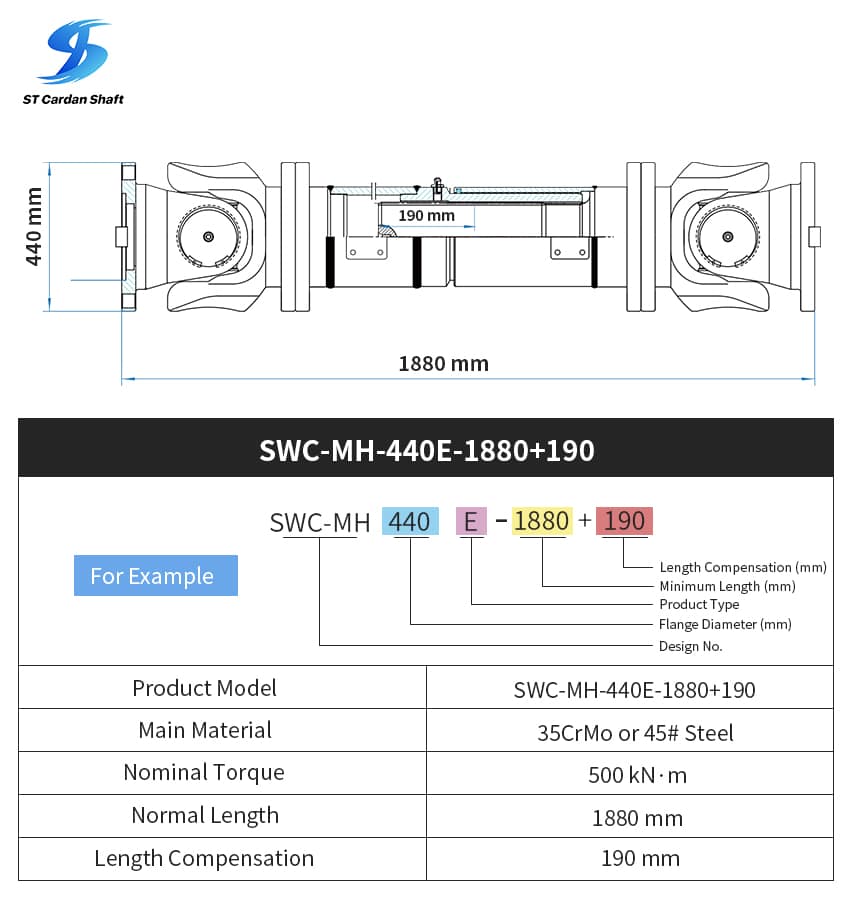

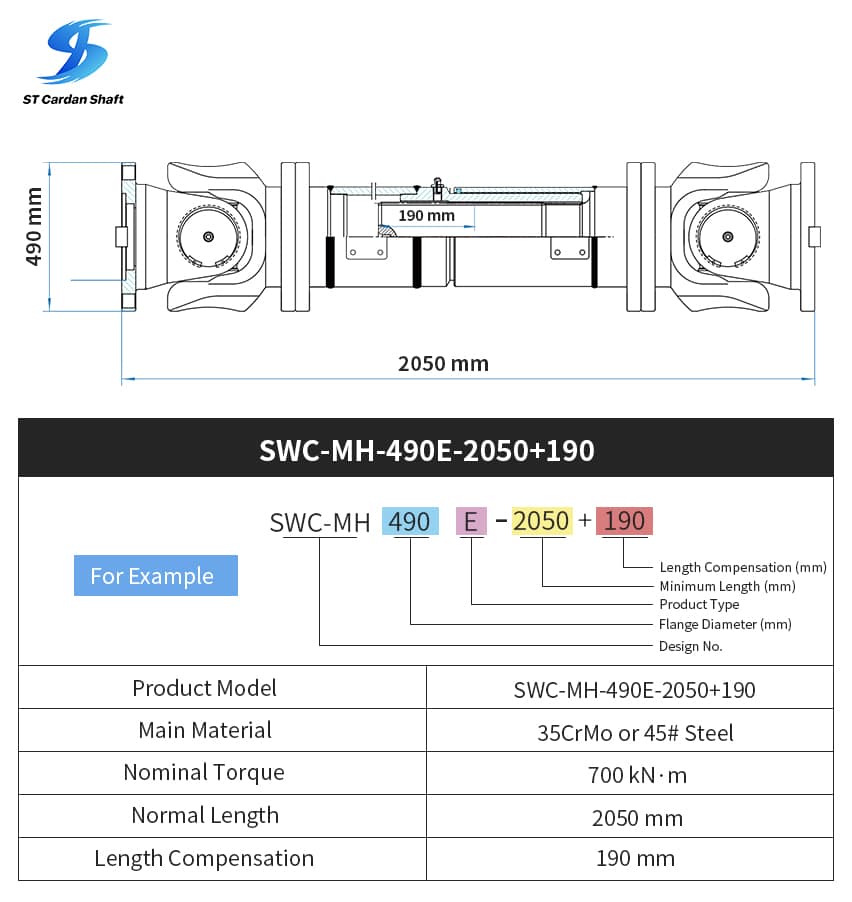

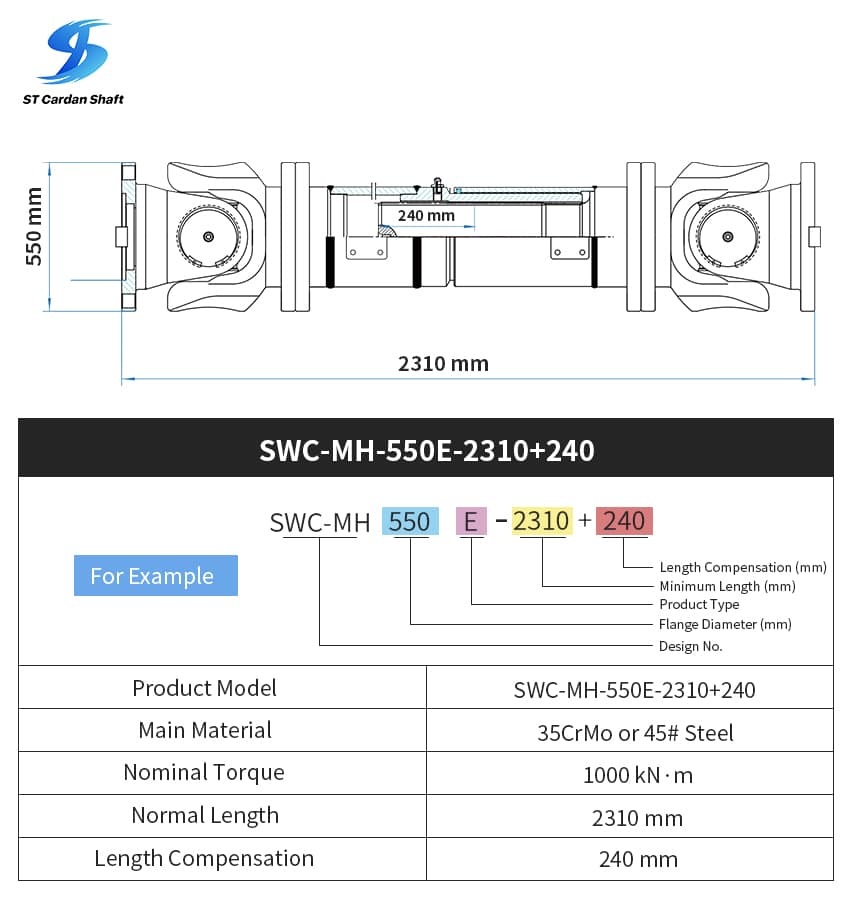

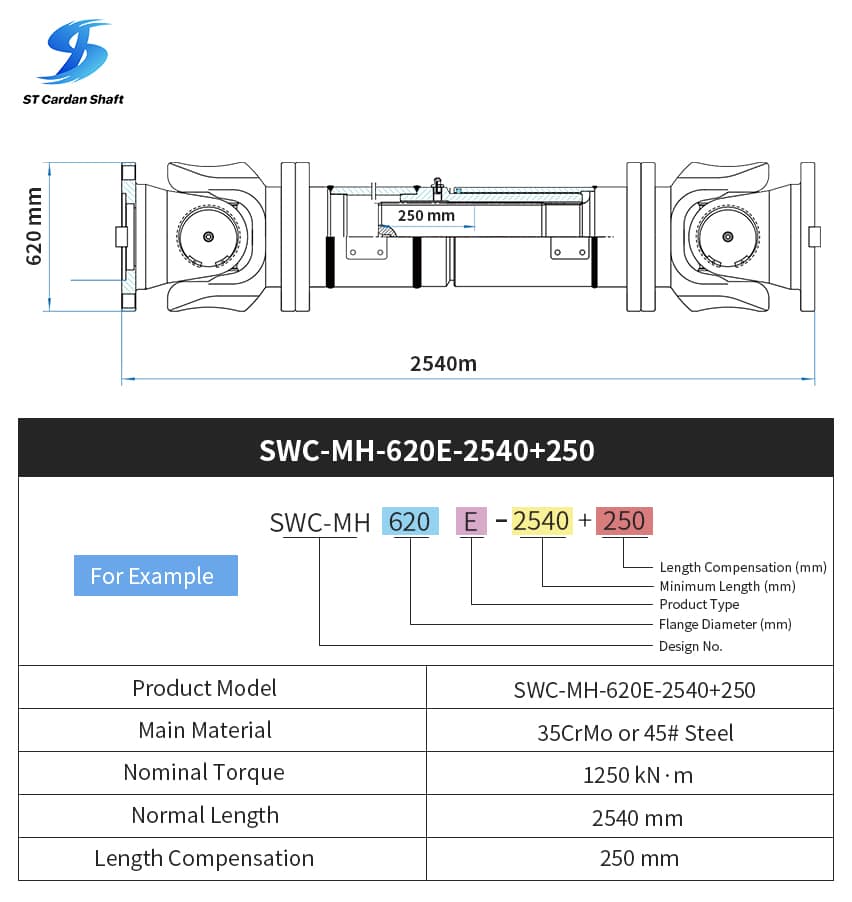

Below are the technical drawings and detailed product parameters for the Type E Series.

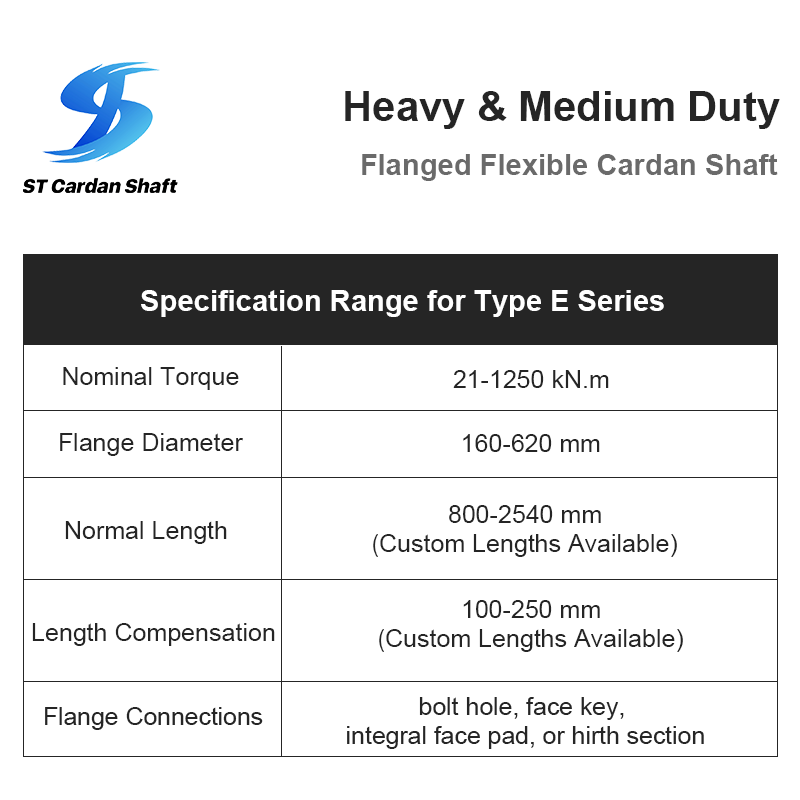

Design and Data Sheet – Heavy & Medium Duty Type E Series:

| Model | SWC-MH-160 | SWC-MH-180 | SWC-MH-200 | SWC-MH-225 | SWC-MH-250 | SWC-MH-285 | SWC-MH-315 | SWC-MH-350 | SWC-MH-390 | SWC-MH-440 | SWC-MH-490 | SWC-MH-550 | SWC-MH-620 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 800 | 850 | 940 | 1050 | 1120 | 1320 | 1440 | 1550 | 1710 | 1880 | 2050 | 2310 | 2540 |

| Lv | 100 | 100 | 120 | 140 | 140 | 140 | 140 | 150 | 170 | 190 | 190 | 240 | 250 |

| m (kg) | 70 | 92 | 126 | 168 | 238 | 340 | 472 | 660 | 806 | 1230 | 1625 | 2388 | 3135 |

| Tn (kN.m) | 21 | 28 | 40 | 56 | 80 | 120 | 160 | 225 | 320 | 500 | 700 | 1000 | 1250 |

| Tf (kN.m) | 10.5 | 14 | 20 | 28 | 40 | 58 | 80 | 110 | 160 | 250 | 350 | 500 | 625 |

| β (°) | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| D | 160 | 180 | 200 | 225 | 250 | 285 | 315 | 350 | 390 | 440 | 490 | 550 | 620 |

| Df | 160 | 180 | 200 | 225 | 250 | 285 | 315 | 350 | 390 | 440 | 490 | 550 | 620 |

| D1 | 137 | 155 | 170 | 196 | 218 | 245 | 280 | 310 | 345 | 390 | 435 | 492 | 555 |

| D2 (H9) | 100 | 105 | 120 | 135 | 150 | 170 | 185 | 210 | 235 | 255 | 275 | 320 | 380 |

| D3* θ | 110 | 121 | 140 | 152 | 168 | 194 | 219 | 245 | 273 | 299 | 325 | 402 | 426 |

| Lm | 95 | 105 | 110 | 125 | 140 | 160 | 180 | 195 | 215 | 260 | 270 | 305 | 340 |

| k | 16 | 17 | 18 | 20 | 25 | 27 | 32 | 35 | 40 | 42 | 47 | 50 | 55 |

| t | 4 | 5 | 5 | 5 | 6 | 7 | 8 | 8 | 8 | 10 | 12 | 12 | 12 |

| n | 8 | 8 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 16 | 16 | 16 | 16 |

| d | 15 | 17 | 17 | 17 | 19 | 21 | 23 | 23 | 25 | 28 | 31 | 31 | 38 |

| b | 20 | 24 | 32 | 32 | 40 | 40 | 40 | 50 | 70 | 80 | 90 | 100 | 100 |

| g | 6.0 | 7.0 | 9.0 | 9.0 | 12.5 | 12.5 | 15.0 | 16.0 | 18.0 | 20 | 22.5 | 22.5 | 25 |

| ML(kg) | 2.57 | 3 | 3.85 | 3.85 | 5.17 | 6.75 | 8.25 | 10.6 | 13 | 18.5 | 23.75 | 29.12 | 38.08 |

| Flange Bolt | |||||||||||||

| Size | M14 | M16 | M16 | M16 | M18 | M20 | M22 | M22 | M24 | M27 | M30 | M30 | M36 |

| Tightening torque (N.m) | 180 | 270 | 270 | 270 | 372 | 526 | 710 | 710 | 906 | 1340 | 1820 | 1820 | 3170 |

Key Product Features:

● Flexible flanged design – accommodates misalignment while maintaining strong torque delivery.

● Customizable length – 520–1,720 mm standard, with options for tailored equipment layouts.

● High torque capacity – supports up to 1,250 kN·m, suitable for demanding industrial drives.

● Flange adaptability – 160–620 mm flange diameter, compatible with diverse machinery setups.

● Smooth and reliable – flexible connection helps reduce vibration, protecting connected components.

● Custom connection options – bolt hole, face key, integral face pad, or hirth section available. Companion flange adapters can be tailored upon request.